Because of the increasing competitive pressure and continuous development of technologies, the quality needs of the organization are constantly rising. The rising customer anticipations are also making organizations aim for the continuous enhancement of their processes. At this stage, the utilization of quality management software is suggested. Quality management software enhances and controls quality and can be incorporated into the organization’s management process.

SAP QM is an important module of SAP that is useful for performing quality functions like quality assurance, quality control, and quality planning at several stages like the in-process manufacturing process stage, the incoming material stage, and after production also. Top organizations like The Hershey Company, Collins Aerospace, Bristol Myers Squibb, and Jabil Healthcare use SAP QM. In this SAP QM tutorial, you will learn to create a plant, inspection method, inspection plan, and inspection lot in the SAP QM.

| SAP QM Tutorial - Table of Contents |

What is SAP QM?

SAP QM is one of the crucial modules of SAP that controls product quality. Whereas other SAP software can run our warehouse effectively and ensure that the flow of services and goods is maximum. They cannot assure the quality of the products that we handle. Thus, for maintaining the quality of the products, it is better to utilize the SAP QM.

It includes complementary components that are useful in the management of materials, production planning, and plant maintenance. The SAP QM can be useful in the warehouse and can be utilized in the materials inspection since it can monitor manufacturing operations. This enables the manufactured and processed materials to be checked before they can be unleashed and reach the warehouse.

It can integrate with other ECC elements like Sales and Distribution, Materials Management, Production Planning, Plant Maintenance, Controlling, Human Resources, and Finance.

| If you want to enrich your career and become an SAP QM professional, enroll in " SAP QM Training".This course will help you to achieve excellence in this domain. |

What are the Key Elements of the SAP QM Module?

SAP QM is utilized mainly in the quality control processes that enterprises can utilize on the goods since they move across the product lifecycle, like inspecting the goods since they come into the facility when they go across the production, and when they go across production, and when they have been shipped as the finished goods.

It includes tools for various interconnected activities that we can configure for a particular process of an enterprise. Each of these tools includes functions that are precise to that activity. These tools are:

- QM-PT(Quality Planning): It allows you to handle and set up quality inspection plans that specify what goods are inspected, how the inspections happen, the characteristics of the goods to be inspected, and the kind of equipment utilized for performing the inspections.

- QM-IM(Quality Inspection): It enables you to evaluate whether the product satisfies the defined quality requirements and for recording the inspection results. QM-IM utilizes the inspection specifications that are specified in the Quality Planning.

- QM-CA(Quality Certificates): It enables us to certify the goods that have satisfied the specified quality requirements. It can have particular criteria for the quality of the goods, and you can affirm the quality certificates to take this into consideration. But. Quality Certificates can also create general certificates that don’t utilize particular criteria.

- QM-QN(Quality Notifications): It allows you to record the problems you face with the goods received from the vendor when the goods will be in production, or that are reported by the users. QM-QN will be configured for recording, managing, and processing positive information about the products and complaints about quality.

- QM-QC-AQC(Quality Control): It enables you to handle the quality control process. For instance, we can utilize the inspection results for updating the quality levels, utilize control charts for controlling the characteristic value, and update the vendor validations for the procurement process.

- QM-IT(Test Equipment Management): It enables you to handle the information about test equipment in the quality inspections. We can preserve the data for every test equipment piece and ensure it is fine-tuned regularly.

[Related Article: SAP QM Interview Questions]

Features and Benefits of SAP QM

- Segregated applications for quality issues and activities

- Limited visibility with no “old-fashioned” applications.

- Absence of role-based screens.

- Capabilities of the cost assignments and cost analysis

- Higher focus on the compliance related issues

- Disparate applications landscapes -MES*, LIMS*, ERP

- Association with a wide range of applications

- Flexible Management and Deployment of the SW solutions

SAP QM - Organization Structure

1. Define Plant

In SAP, Plant is the independent, highest, and physical organizational unit in the SAP MM module. It can be a manufacturing unit or an operational unit, or the sales branch of the organization. From the material management perspective, we can define the plant as the location that stores valued stock.

The plant is accountable for the procurement, planning, and distribution of goods & services to the consumers to the other resources of the enterprise in one company code.

How do we create a plant in the SAP?

We can create the plant through one of the below navigation methods:

| Plant | Name |

| TKBL | TKBL - Bangalore Plant |

| TKUS | TKUS - US Plant |

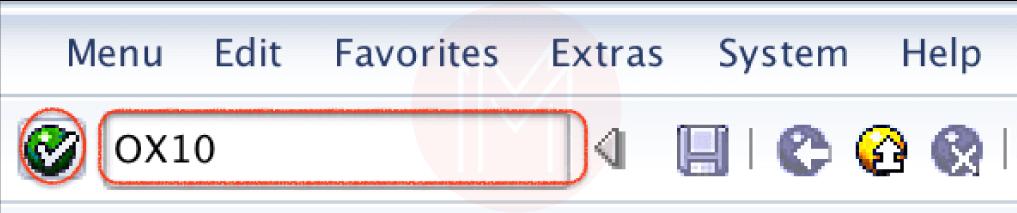

- Transaction code: OX10

- Menu_Path: SPRO/IMG/Enterprise Structure/Definition/Logistics - General - Define, delete, copy, checkpoint.

Step 1: write T_Code “OX10” in the command and press “execute.”

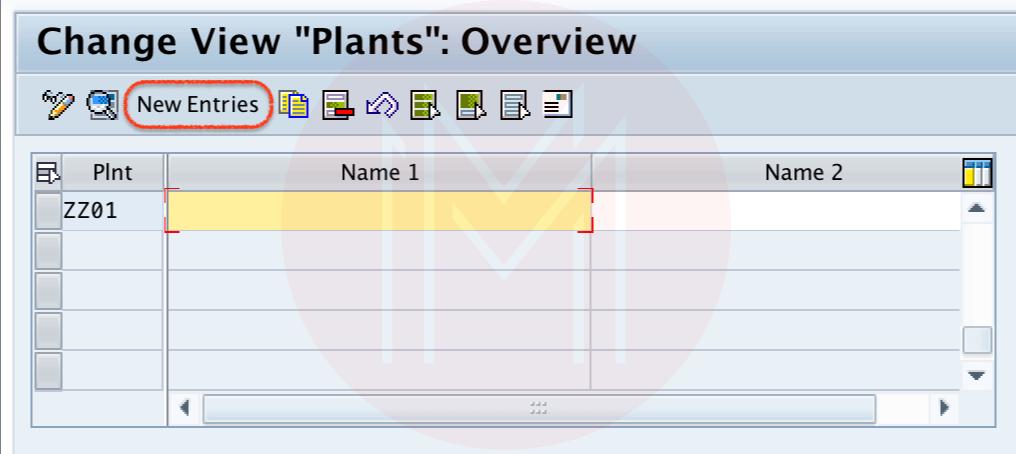

Step 2: On the change view plants overview screen, press the new entries to define the new plant according to the organizational needs.

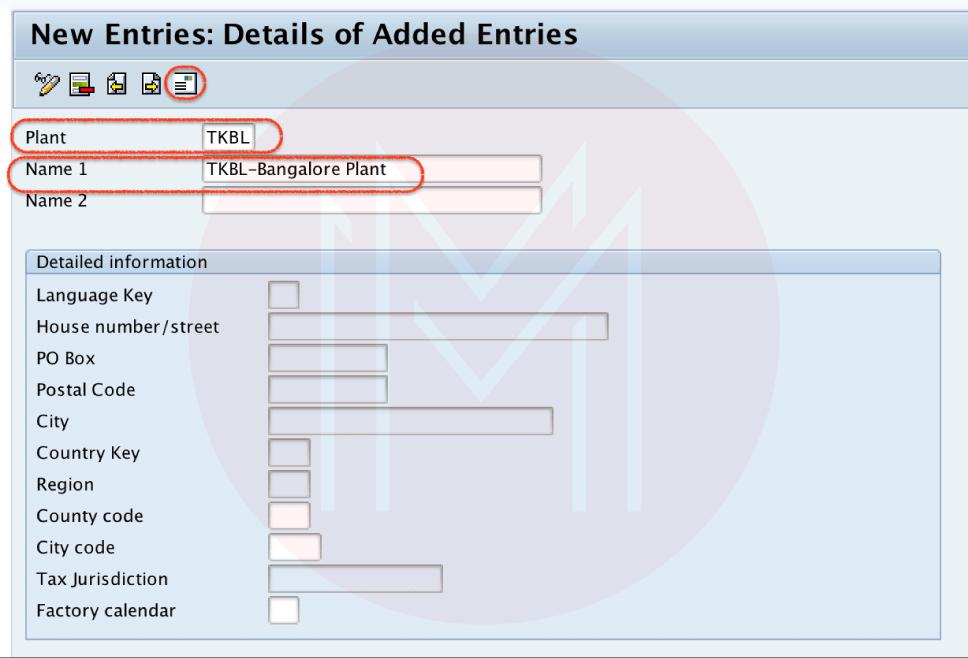

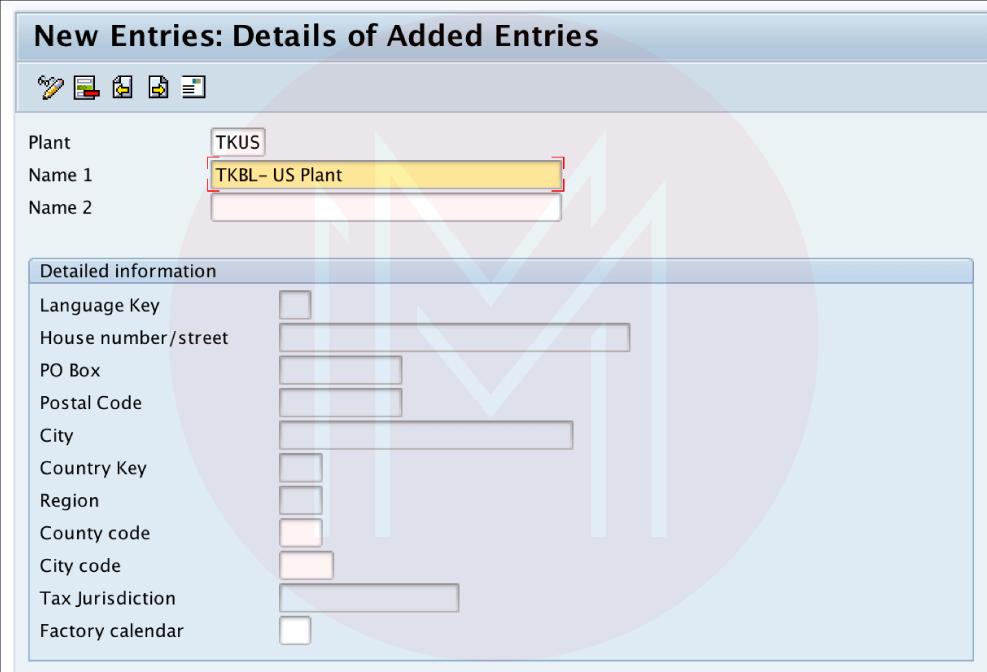

Step 3: On the new entries screen, update the below details:

- Plant: Type the four digits key that can identify the Plant in the SAP.

- Name: Update the descriptive name of the plant

After updating the plant description and code, press the address button for updating the plant address.

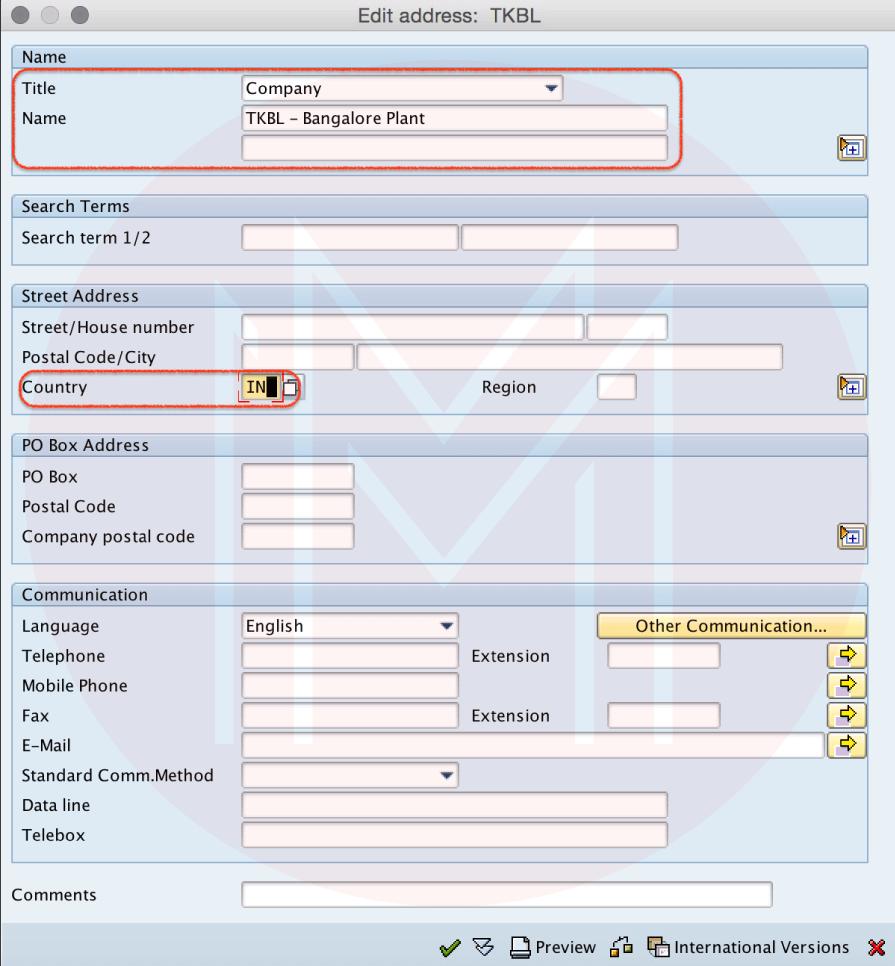

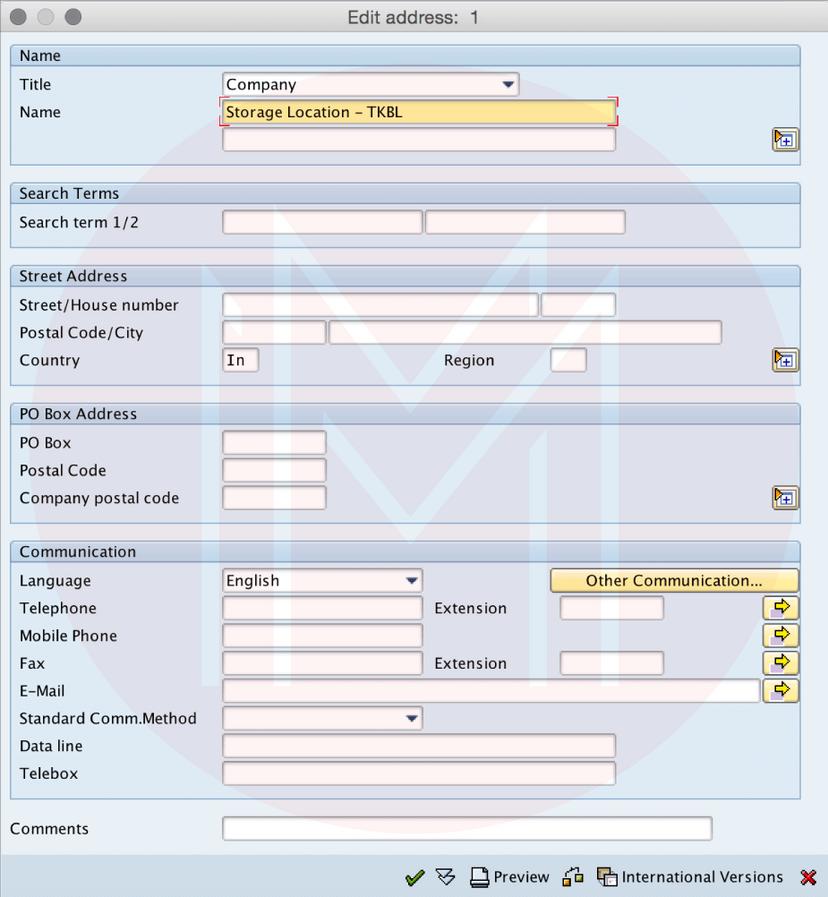

Step 4: Now update all the mandatory and required details in the address screen.

Press the save button, select the personalizing request, and store the configured plant details. Press the next entry button(F8) and likewise create another plant TKUS with the necessary details.

2. Define the Storage Location

Storage Location is the part of the plant where the stocks are physically maintained and stored within the plant. Every storage location can include its own address in the plant.

- It is needed for maintaining one storage location for one plant.

- One plant can have several storage locations.

How to define the storage location in the SAP

We can configure the storage location through the below navigation method:

- Transaction code: OX09

- Menu path: “SPRO/IMG/Enterprise Structure/Definition/Material Management/Maintain Storage Location.”

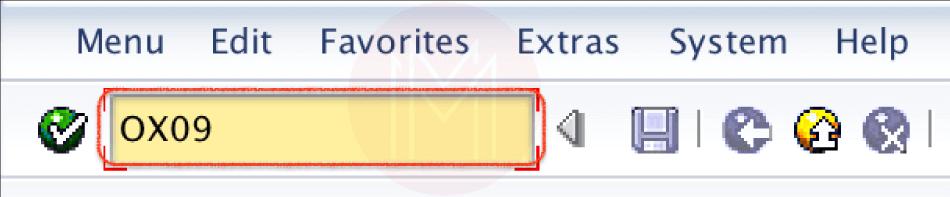

Step 1: Write T-code “OX09” in the SAP command field and enter.

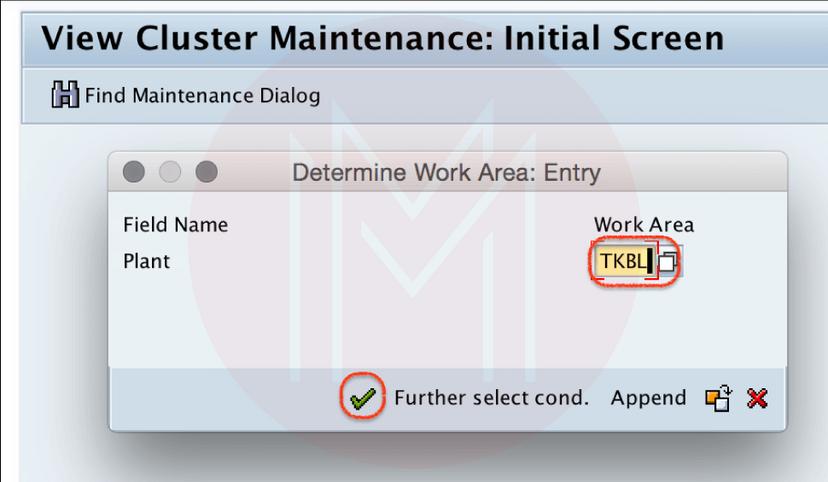

Step 2: You will be prompted for entering the plant key, update the plant code in the provided work area field as displayed below, and click on “enter” to continue.

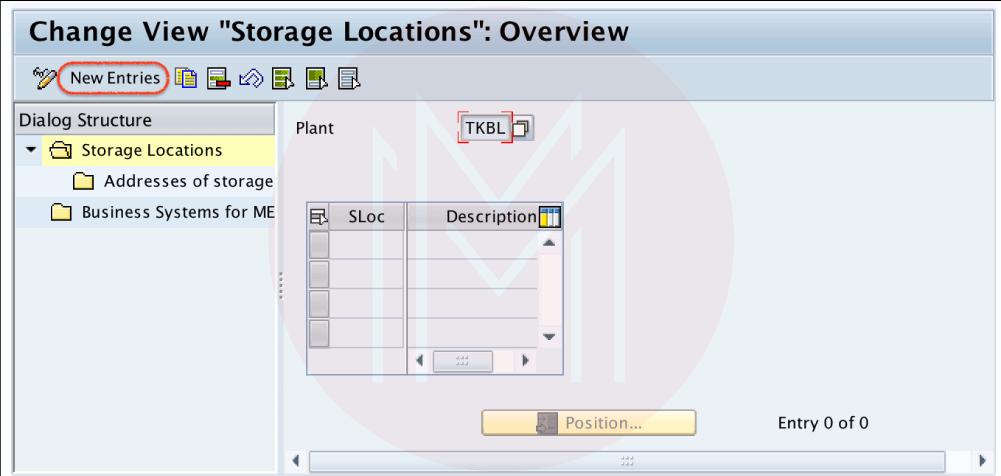

Step 3: In the change view “storage locations” overview screen, press the new entries button for defining the new storage locations according to the requirements.

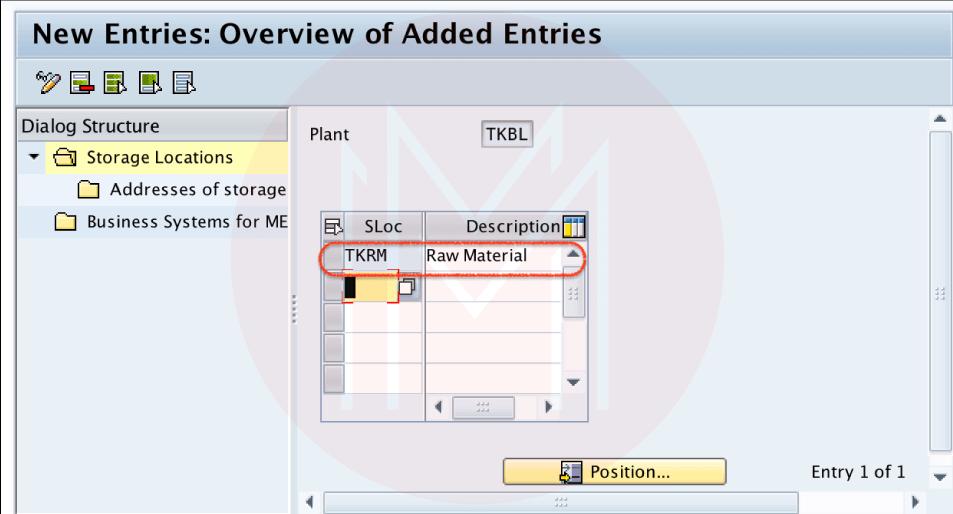

Step 4: In the new entries storage location screen. Update the below details:

- SLoc: Type the four digits key that detects the storage location in the SAP.

- Description: Update the storage location description.

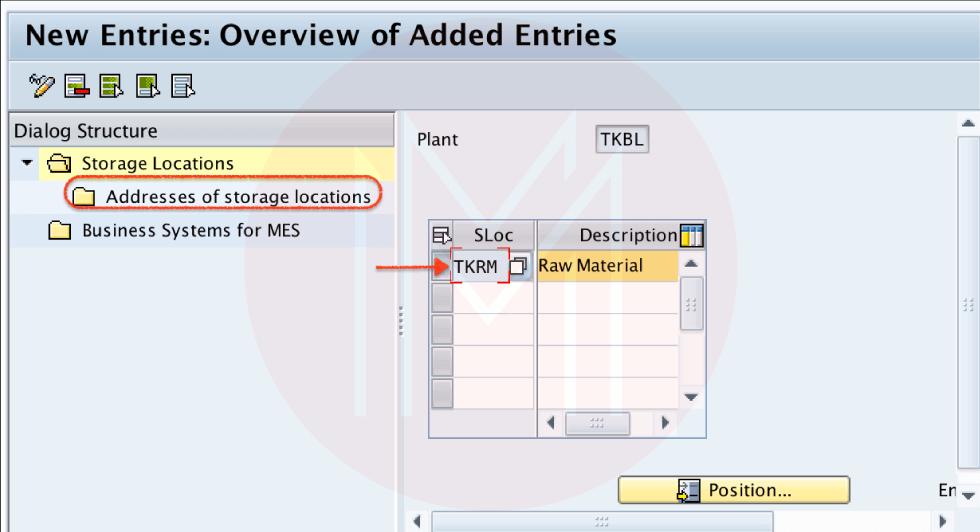

Step 5: Now choose the storage location key and press the address of the storage location in the dialog structure.

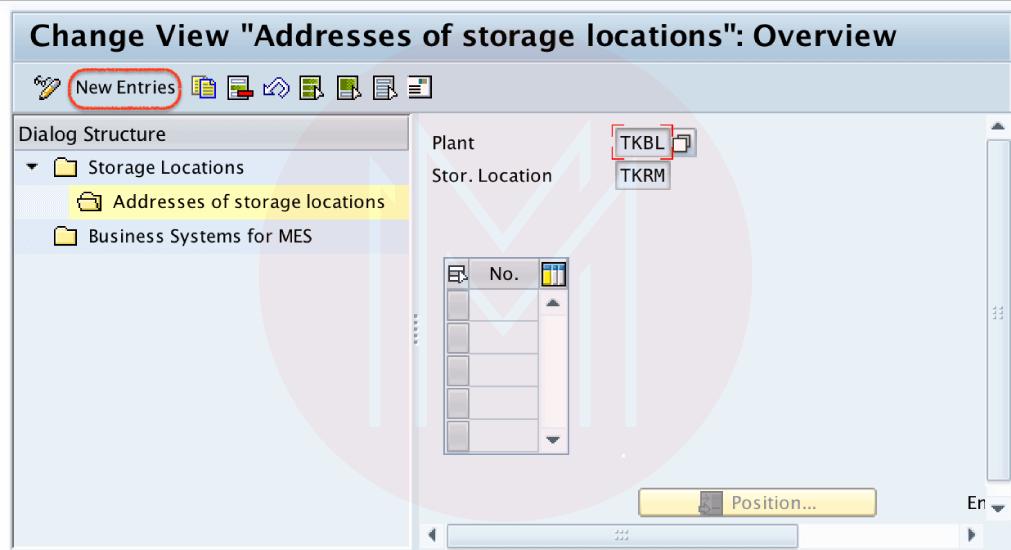

On the change view addresses of the storage locations overview screen, press the new entries button to update the storage location address.

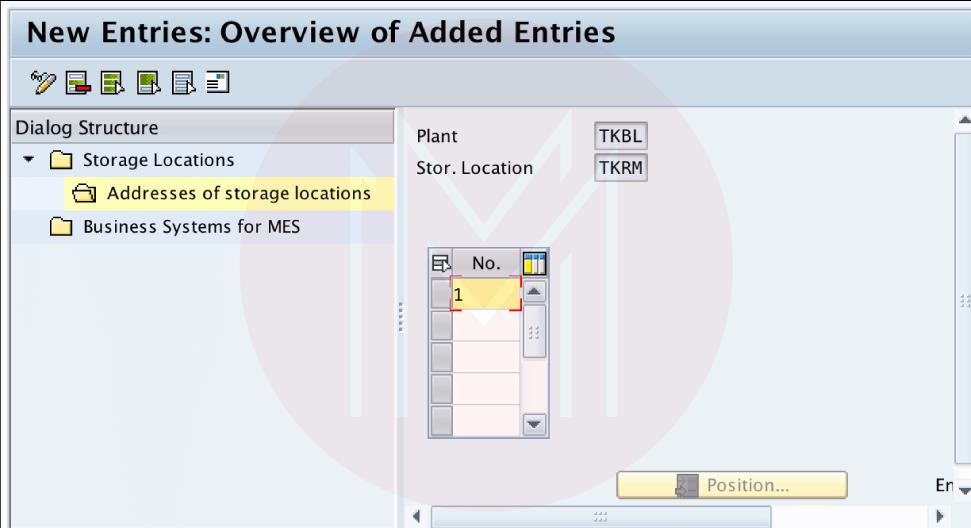

Update the number in Field.no, and you can update up to three characters. After updating the No, press enters to continue, and you will be redirected to another screen for the entry of the secondary information.

Update the necessary details like address with city, telephone number, etc.

After updating all the necessary details, press the save button and save the details of the configured storage location.

SAP QM - Master Data

1. Create Master Inspection Characteristic

Configuration steps:

| SAP TCode | QS21 |

| SAP Path | SAP Menu/ Logistics /Quality Management /Quality Planning/ Basic Data/Inspection Characteristic/Create |

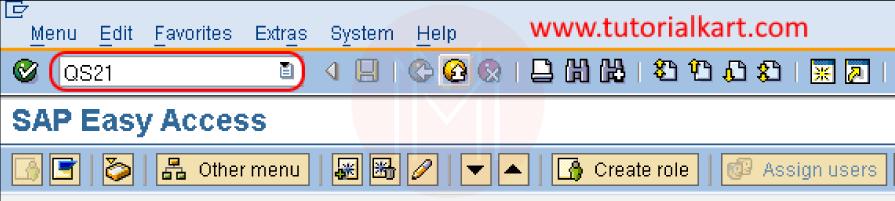

Step 1: Run the execution code “QS21” in the SAP command field.

Step 2: In the next screen, “Create Master Inspection Characteristic: Initial Screen,” enter the below details

- Plant: Type the plant code for which inspect characteristic that we are creating for

- Master Insp.chart: Type the new key that defines the master inspection characteristic in the SAP.

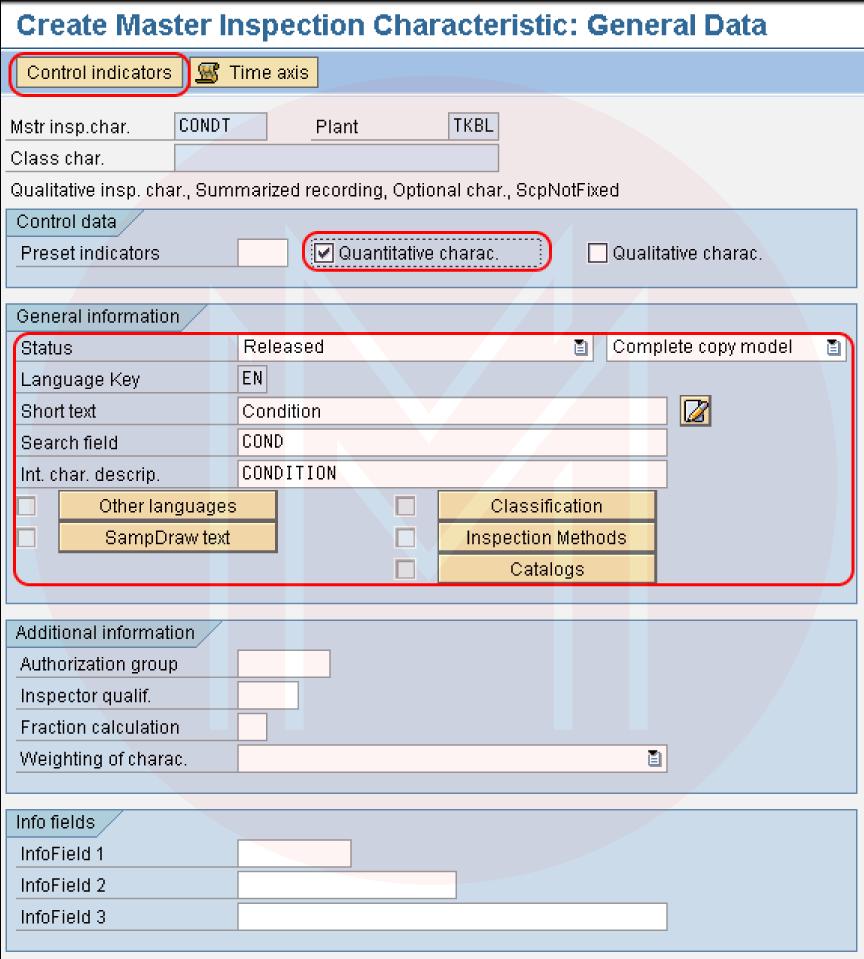

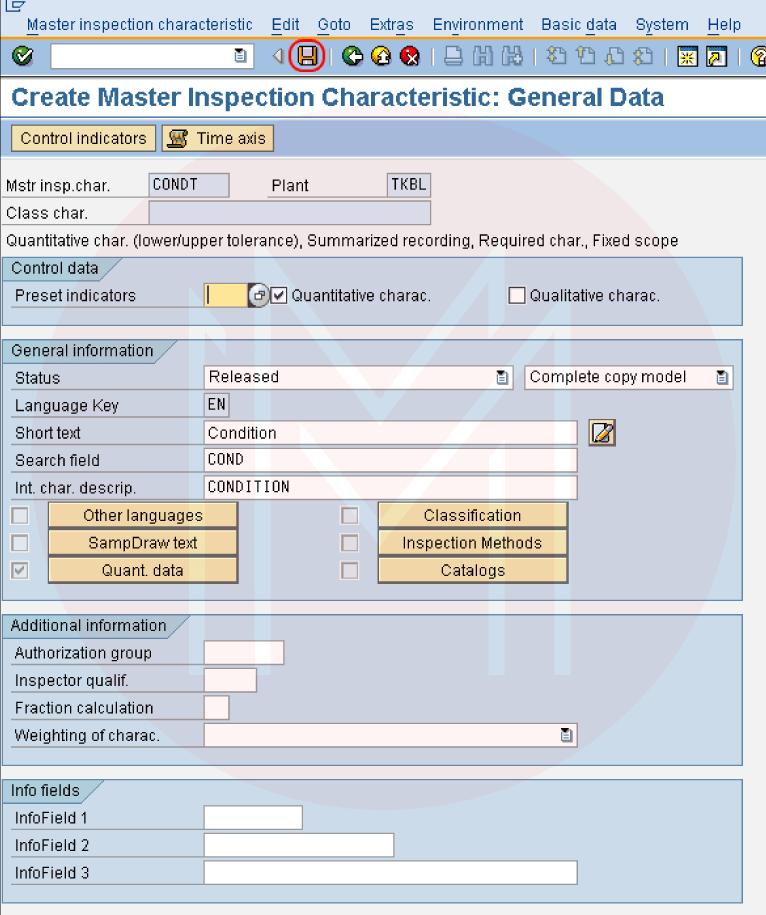

Step 3: In the next screen, “Create master inspection general characteristic data,” update all the needed details.

- Control Data: Verify the quantitative option characteristic

- Status: Update status as “Released” and Complete the copy model

- Short: Update the short description of the inspection characteristic

- Search Field: Update the key for the search field

- Description: Update the description of the inspection characteristic

After providing all the necessary details, press the control indicators.

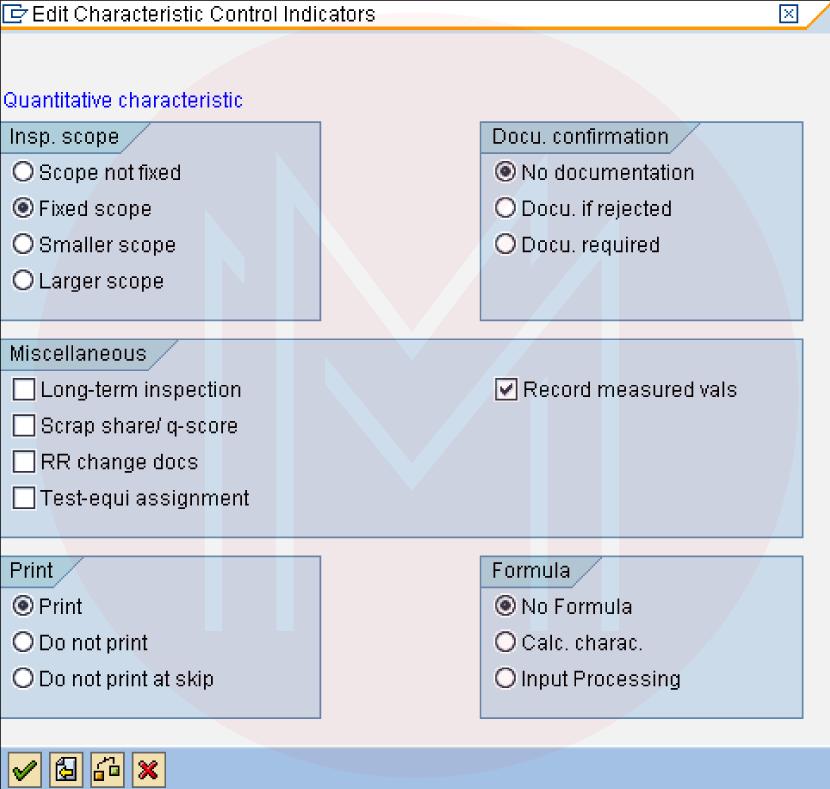

Step 4: In the following screen, “Edit characteristic control indicators, check the necessary option for

- Sample

- Type

- Results Confirmation

In the following screen, select the necessary details and click enter to continue.

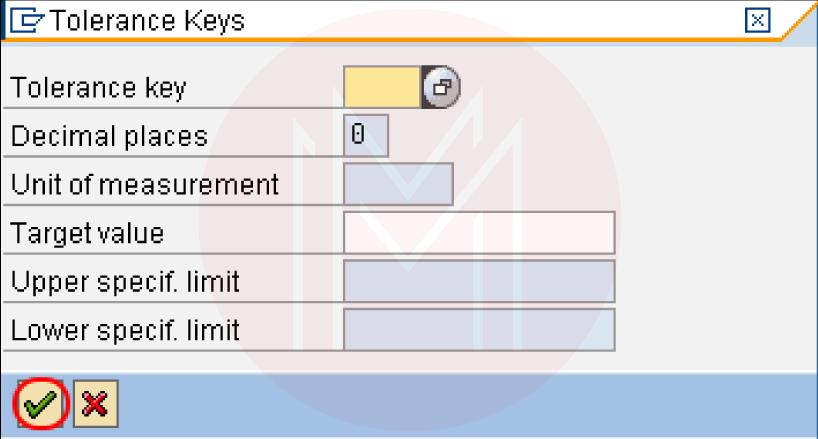

Step 5: A tolerance keys screen displays for entering the tolerance details; click enter for providing the details for tolerance.

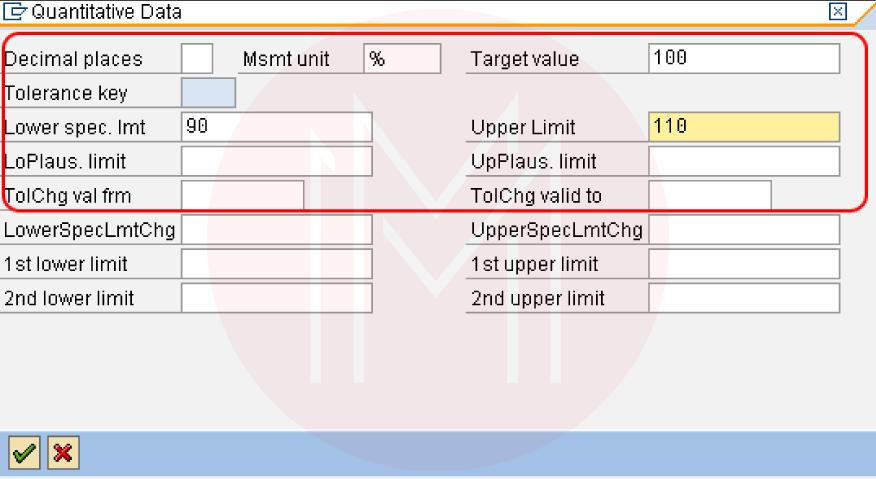

In the following screen quantitative data, update the necessary details like target value, upper limit, lower limit, measurement unit, etc, according to the requirements.

After updating all the necessary details of the quantitative data, click enter for continuing. After maintaining all the necessary details for the master inspection characteristic, select the save icon and save the configured details in the SAP.

2. Define the Condition types for the output determination in the SAP

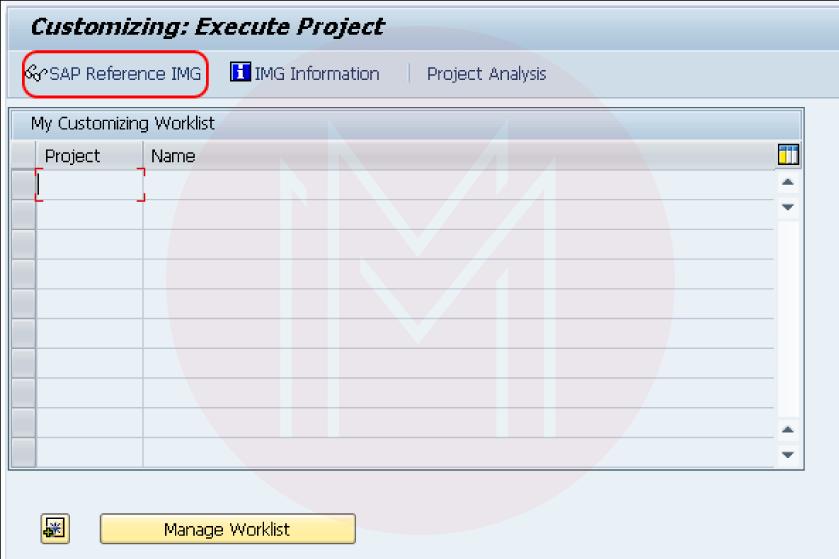

Step 1: Execute the tcode “SPRO” in the SAP command field

Step 2: Select the “SAP Reference IMG.”

Step 3: In the next screen, show IMG, go to the navigation menu path - quality management/quality certificate/ output determination, and select img activity “Define condition types for the output determination.”

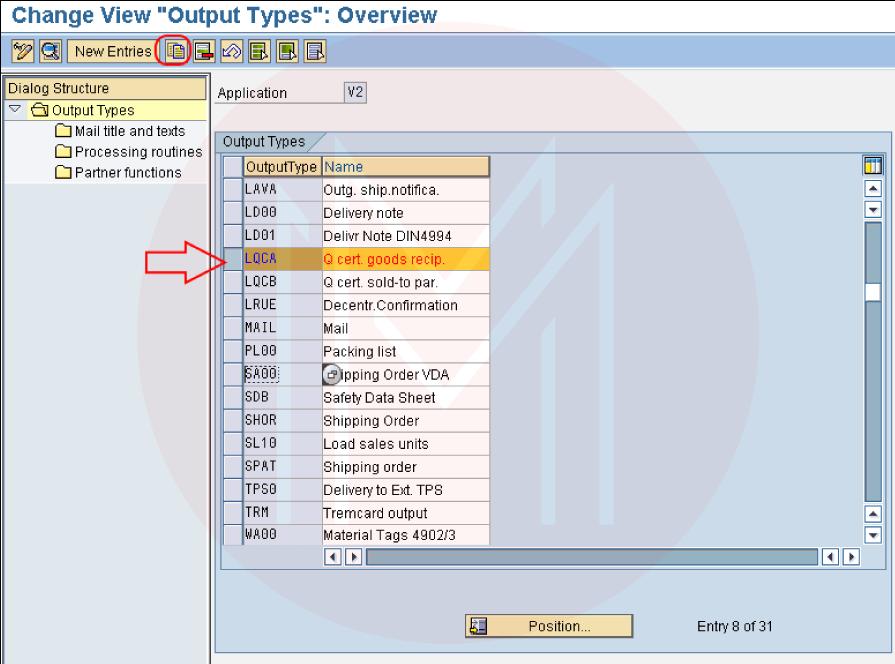

Step 4: In the following screen, show the output types overview and show the list of the defined output determination on the screen. We can specify the new condition types for the output determination in the SAP. Press the “Pencil” button for modifying or changing the output types.

Now we can define the new condition types for the output determination through the new entries option or by copying the function from the existing output types.

Select the existing output type to copy and click on the copy as the option.

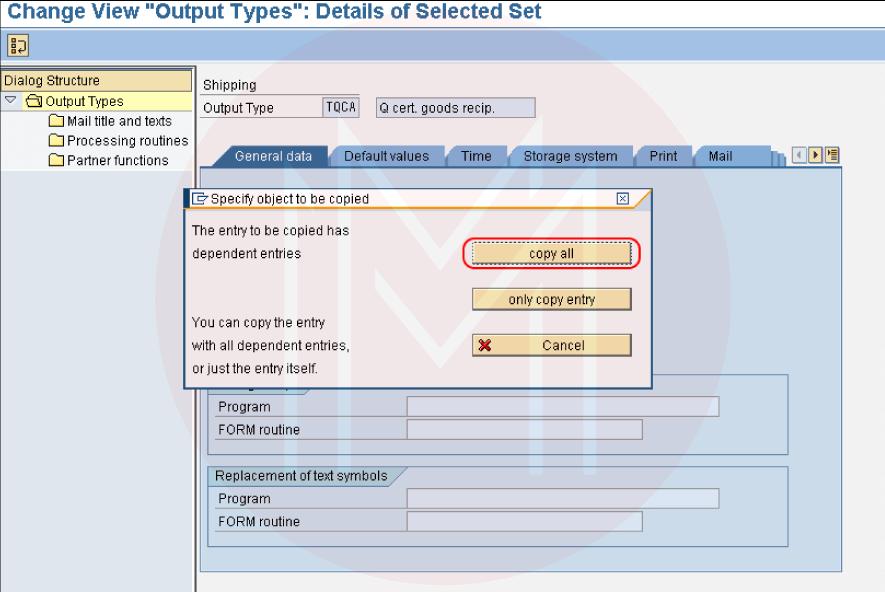

Step 5: In the following screen, enter the output type name, description, and the necessary details, and click entire to continue.

Select copy All for copying all the entries from the existing output types to the latest output types.

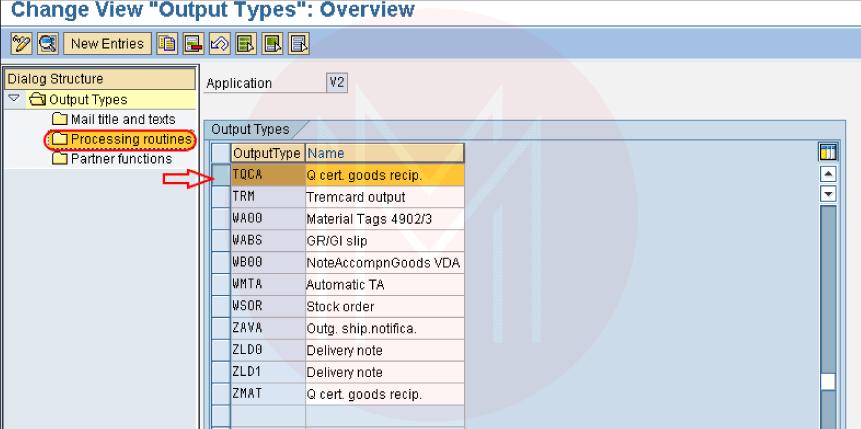

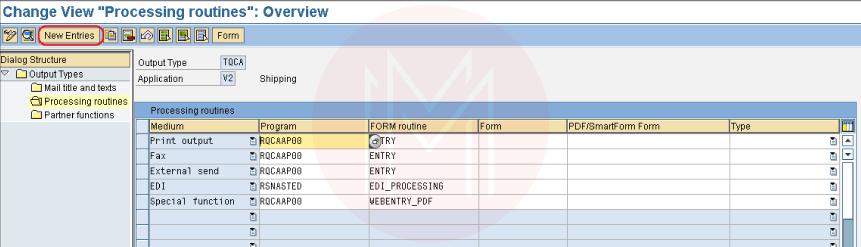

Step 6: Select the output type from the main screen, and press the processing routines.

Press the new entries for maintaining new processing routines in the SAP.

In the latest entries screen, provide the necessary details, and press the save icon.

Step 7: Go back to the main screen and select output type, and press on the partner functions.

In the next screen, change the view partner function views, and press the new entries.

In the latest entries partner functions screen, enter the necessary details as displayed below. Click on the “save” icon and save configured condition types for the output determination in the SAP.

3. Create the Inspection Method in SAP

In the SAP, the inspection method explains how the inspection is to be performed for the inspection characteristics:

- What kind of inspection is to be carried out

- Validity

- Text

- Classification

- Qualification

Configuration steps

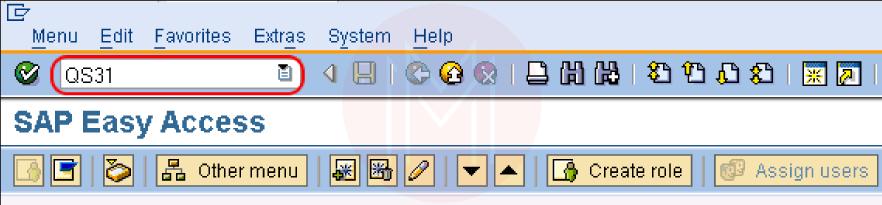

In SAP, we can create the inspection method through the transaction code “QS31” or the menu path.

- Transaction code: QS31

- Path: “SAP Menu/Logistics/Quality Planning/Quality Management/Basic Data/Inspection method/QS31.”

Step 1: Execute transaction code “QS31” in the SAP command field and click enter to continue.

Or

Go to the navigation menu path logistics - Quality Planning - Quality Management - Basic Data - Inspection Method and press “create.”

Step 2: In the next screen, “create inspection method: initial screen,” update the below details

- Plant: Type the plant code or select the plant key from the drop-down list.

- Inspection Method: Enter the inspection method name or procedure for creating in the SAP.

- Valid from updating the validity date from the which data that inspect method will be valid.

After updating the details, press the inspection method.

Step 3: In the following screen, “Create the inspection method: General data,” update the below details

- Language Key: By default, the language key will be “English”(EN).

- Status: Select the option as released for releasing the inspection method or procedure.

- Search field: Enter the search field to search for the inspection method.

- Short Field: Update the short description or the long text according to the requirement.

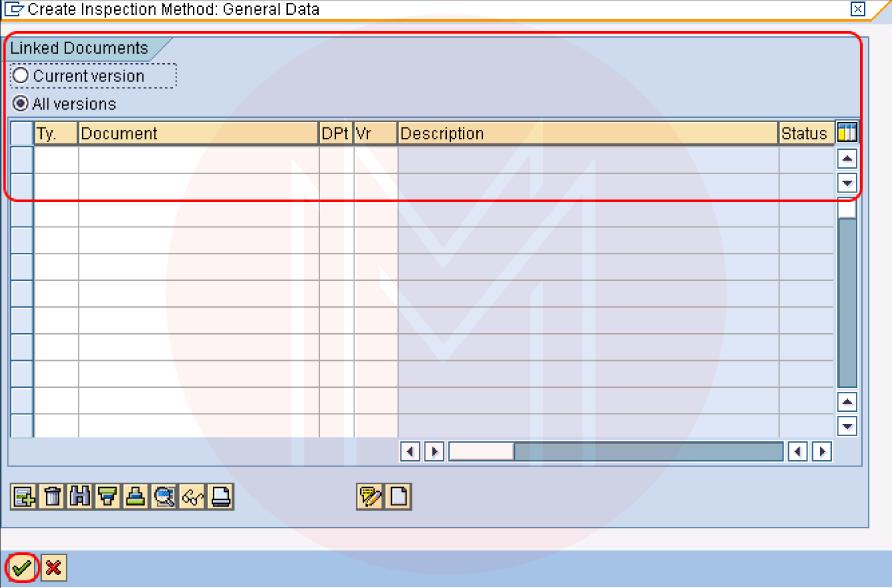

After entering details, press the documents for linking the document.

Step 4: In the following screen, “Link Document,” enter the below details.

- Versions: Select the option “all versions.”

- Document: Type the Document Number

- Type: Give the Document Type

- DPt: Type the document version and type

After updating every detail, click enter to continue.

Now press the save icon and save the created inspection method in the SAP QM.

[Related Article: SAP Interview Questions]

SAP QM - Inspection Planning

1. How do we create the inspection lot in the SAP?

In SAP, the inspection lot enables you to inspect the goods, record inspection results, record the defects of the goods, and finish the inspection process with a customized decision. For inspecting a piece of equipment or material, an inspection lot should be created in the SAP QM.

In SAP QM, inspection lots will be maintained automatically manually, or system by the user, and these inspection lots will be for different kinds of inspections.

| Transaction Code | QA01 |

| SAP Path | SAP Menu/Logistics/ Quality Management / Quality Management / Quality Inspection / Inspection Lot / Create |

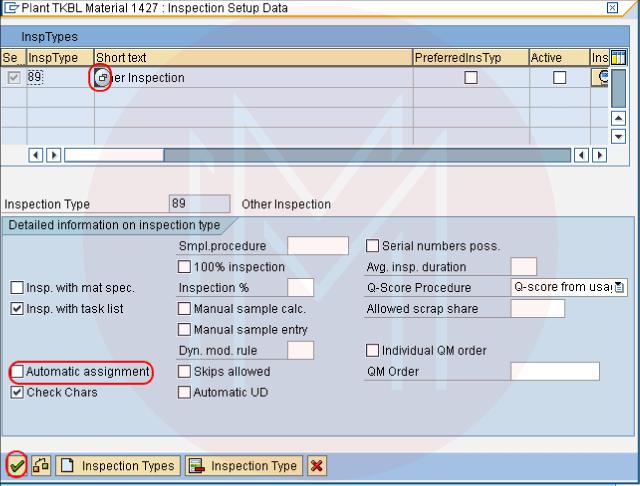

We can follow the below steps for activating the valid inspection type for the material.

Step 1: Open the tcode “MM02” and enter the necessary material code.

Step 2: Select the view “Quality Management,” and update the necessary details for the procurement data and press the inspection setup.

Step 3: Press “Create inspection type.”

Step 4: Press the drop-down list and select the inspection type from the list and click enter.

- Assigned Inspection type 89 to the material. Select the save icon and save details.

Procedure for creating the inspection lot in the SAP

Step 1: Execute SAP tcode “QA01” in the SAP command field

Step 2: In the following screen, create the inspection lot manually: initial screen, enter the below details:

- Plant: Enter the plant

- Material: Enter the material number

- Inspection lot origin: Enter the inspection lot origin that defines how the inspection lot is to be processed and created. Inspection lot origin is predefined in the SAP, and we cannot define new inspection lot origin in the SAP system.

- After entering the details of the material, plant & inspection of the lot origin, click enter for continuing.

Step 3: In the next screen, create the inspection lot manually: origin, enter the below details

- Ins.Lot Qty: Enter the quantity of the inspection lot

- Start date: Enter the starting date of the inspection lot

- End date: Enter the ending date of the inspection lot

Select the save icon and save configured inspection lot in the SAP.

2. How to create the inspection plan?

In SAP, we create the inspection plan for different purposes like inspection of the preliminary series, inspection of the model, inspection of materials, inspection of goods issues, etc.

| Transaction Code | QPO1 |

| SAP Menu Path | SAP Menu/Logistics/Quality Management /Quality Planning/Inspection Plan/ Create |

Step 1: Execute transaction code “QP01” in the SAP command field.

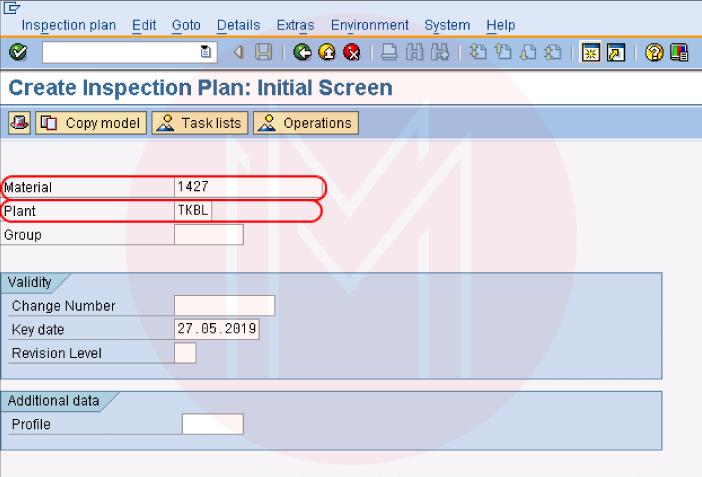

Step 2: In the next screen, “Create Inspection Plan: Initial Screen,” enter the below details:

- Material: Enter the material number for which we have to create the inspection plan

- Plant: Enter Plant code

After updating the plant and material, press enter to continuing

Step 3: In the next screen, “Create Inspection Plan: Header Details,” enter the below details:

- Usage: Select the material usage

- Description: Update the description inspection

- From lot size: Enter the start lot size or leave from the lot size

- Status: Select the material status(released for costing, released for order, released, etc.)

- Update the necessary details of the parameters for the dynamic inspection or modification points.

- To lot Size: Enter the maximum amount of lot size.

After maintaining all the required fields. Press” task list.”

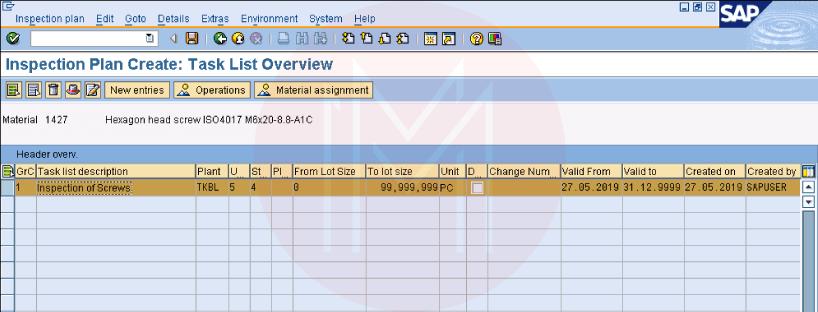

Step 4: In the next screen, the inspection plan creates: a task list overview, it shows the overview inspection plan with the task information and lot sizes of the materials. Press the “operations” option.

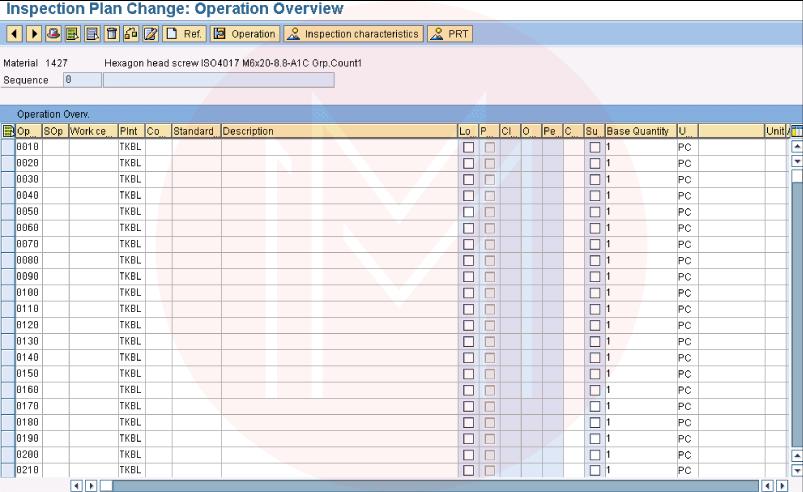

Step 5: In the next screen, the inspection plan, create an operation overview screen, and enter the below details:

- Work Center: Update work center code for assigning to the inspection plan

- Control Key: Enter the Control Key

After providing the control key and work center, press the save icon for saving the configured details.

SAP QM FAQs

1. What are the advantages of the SAP QM?

The following are the most valuable and efficient benefits of SAP QM:

- Greater Customer Satisfaction using enhanced product quality.

- Complete integration in production and procurement offers constant quality assurance.

- Monitoring of the customer and supplier returns by implementing the quality control measures in the SAP QM quality notifications.

- Activation of the necessary corrective actions by the SAP QM system’s automatic quality notifications.

2. What is the role of the SAP QM?

SAP QM(Quality Management) is the element of the SAP ERP Central Component(ECC) that allows businesses to implement and run quality processes. It is developed for preventing defects, allowing continuous process enhancement, and setting up quality control programs.

3. What are the roles and responsibilities of SAP quality management?

The main responsibility of SAP quality management is conducting required design thinking workshops, formalizing the process design with the business, provide detailed specifications.

4. What is Quality Control in the SAP QM?

In SAP QM, quality control includes corrective, monitoring, and preventive activities that utilize default values from the quality planning and assessment of the quality inspection and the quality notification.

5. What are the main features of SAP data quality management?

Following are the some important features of SAP data quality management:

- Address validation and Cleansing

- Cloud Deployment

- Built-in integration to the SAP applications

- Geolocation enrichment services

6. What is the quality level in SAP QM?

Quality level is the data record that automatically updates the dynamic modification time by verifying the modifications for the inspection stage change end.

7. What is QM in procurement in the SAP?

The QM functions apply partially to a particular material, vendor, and material-vendor combination. The control data, thus, are stored partially in the material master.

8. What are QM components?

The following are the components of QM:

- Quality Assurance

- Quality Planning

- Continuous Improvement

- Quality Control

9. What are the 7 QMs Principles?

Following are the 7 QMs Principles:

- Leadership

- Customer Focus

- Engagement of the People

- Improvement

- Process Approach

- Relationship Management

- Evidence-based decision making

10. What is the inspection type in SAP QM?

When the inspection lot will be created, the system utilizes the inspection lot origin for determining how the inspection lot can be processed. Subject to whether the inspection lot is created manually or automatically, the system identifies the inspection type as follows:

- When the system creates the inspection lot automatically, it identifies the inspection type automatically.

- When we create the inspection lot manually, we should define the inspection lot origin. If multiple inspection types is the activity for the material in the material master, the system signals you to select the inspection type.

Conclusion

SAP QM is the element of the SAP S/4 HANA that enables businesses to run ad implement quality control processes. It can prevent defects and develop quality control programs. I hope this SAP QM tutorial gives you detailed information about SAP QM. If you have any queries, let us know by commenting below. you can also enroll in "SAP QM Training" and get a certification.

On-Job Support Service

On-Job Support Service

Online Work Support for your on-job roles.

Our work-support plans provide precise options as per your project tasks. Whether you are a newbie or an experienced professional seeking assistance in completing project tasks, we are here with the following plans to meet your custom needs:

- Pay Per Hour

- Pay Per Week

- Monthly

| Name | Dates | |

|---|---|---|

| SAP QM Training | Mar 03 to Mar 18 | View Details |

| SAP QM Training | Mar 07 to Mar 22 | View Details |

| SAP QM Training | Mar 10 to Mar 25 | View Details |

| SAP QM Training | Mar 14 to Mar 29 | View Details |

Madhuri is a Senior Content Creator at MindMajix. She has written about a range of different topics on various technologies, which include, Splunk, Tensorflow, Selenium, and CEH. She spends most of her time researching on technology, and startups. Connect with her via LinkedIn and Twitter .