- Home

- Blog

- Hardware Design Development

- PLC Interview Questions and Answers

PLCs are used in industrial automation to increase reliability, system stability, and performance, minimizing the need for human operators. It acts as a remote operating device or automatic sensing device.

Engineering students mostly prefer the automation system for doing their academic or research projects. PLC has gained noteworthy popularity in the field of industrial automation and electrical power system analysis.

Before we jump to the PLC interview questions 2024, let us have a look at some interesting facts about PLC:

- The market value of PLC is expected to reach $15.15 billion in 2026.

- The PLC systems can reduce machine downtime from 20% to a minimum of 4%.

- Siemens and Rockwell are the global PLC leaders and have a market share of over 50%.

- The average salary of a PLC programmer in India is INR 3 Lakhs to INR 7Lakhs per annum.

The aforementioned points clearly state the demand for PLC professionals. Put yourself ahead of the crowd by choosing to become a PLC programmer.

MindMajix experts have categorized PLC Interview Questions - 2023 (Updated) into three levels they are:

Top 10 Frequently Asked PLC Interview Questions

1. Explain PLC?

2. What are the different parts of automation?

3. What are the implementations of PLC automation?

7. How does a Latch coil work?

8. What is a draw close to the control relay?

9. How could you take a look at one PLC device?

10. Write different principal organization PLC?

PLC Interview Questions and Answers for Freshers

1. Explain PLC?

Ans: Robot manufacturing companies use programmable logic controllers. It is a digitized computer device. PLC helps in the automation of a few electromechanical tasks. It can control a device connected to electricity to converting electrical energy into mechanical energy.

| If you want to enrich your career and become a professional in Hardware Design Development, then enroll in "Hardware Design Development Online Training" - This course will help you to achieve excellence in this domain. |

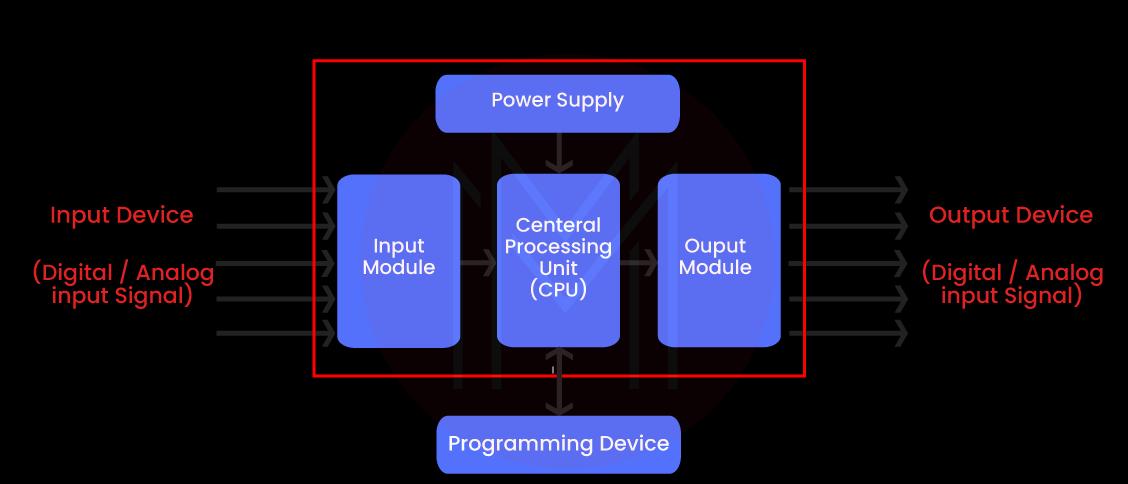

2. What are the different parts of automation?

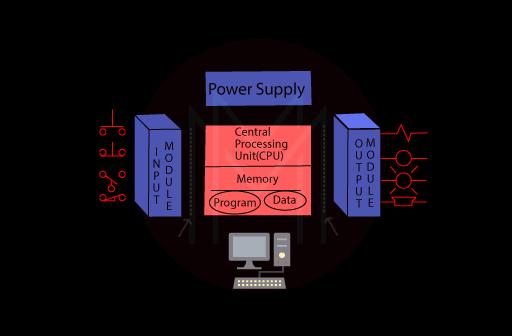

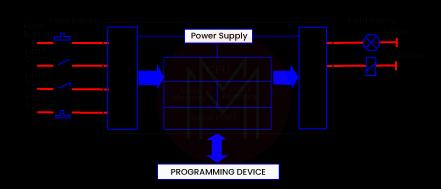

Ans: The various components of the PLC include:

Input/output modules: These are essentially the modules, which depend on the user-supplied input and output commands.

Power Supply: PLC can operate the DC current power supply.

CPU: Central Processing Unit (CPU) is the brain of a computer that stores all commands and data.

Co-processor Modules: Actually, it is a set of microcomputers. It can do different programs. It can support PLC properly to function more efficiently.

Software: PLC needs software that stores and supplies all the commands and data to the PLC and Co-processors.

Peripheral Device: The monitor can be connected by the peripheral device.

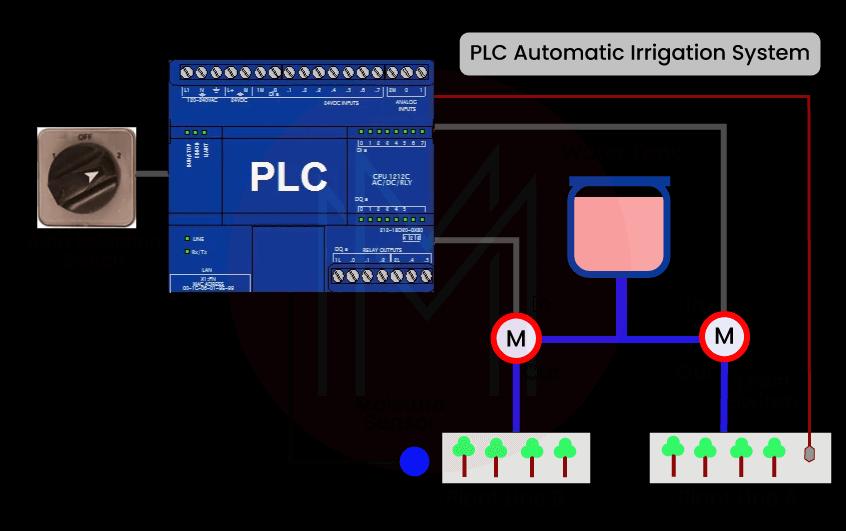

3. What are the implementations of PLC automation?

Ans: The main implementations of PLC are in industries, but other applications of PLC include:

- Driving Motors

- Light Lamps

- Button Switches

- Traffic Signals

- Water Draining Pumps

- Photo Sensors.

4. Role of PLC in Automation?

Ans: PLC is the most crucial part Of automation. PLC can monitor and control all functions. The input is sensed by I/P modules, the logic is processed by the CPU and memory, and the output is given by the output module.

5. What is redundancy in PLC?

Ans: Redundancy means the state of non-usefulness. For PLCs, when they are out of service or when they have faults, they cannot be used. They then become useless and are said to be redundant. It is called PLCs redundancy.

6. What is HMI in PLC?

Ans: The full form of HMI is the Human Machine Interface. It basically allows operators to interface or communicate with the system they are supervising. The HMI provides a graphical overview of the status of the mechanical system and direct control of its operation. Graphical HMI screens can be programmed to allow the operator to view all important status and control information.

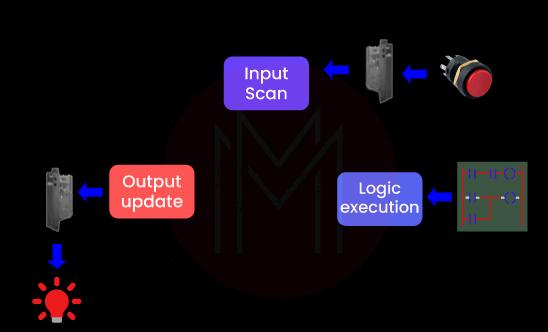

7. What is scan in PLC?

Ans: SCAN means a performance by any sequential program controller operation. The process produces all updated outputs, which correspond to the supplied inputs.

The SCAN process runs in the ladder diagram. total scan time takes to read the input, process the program logic, and update the corresponding output in a single cycle.

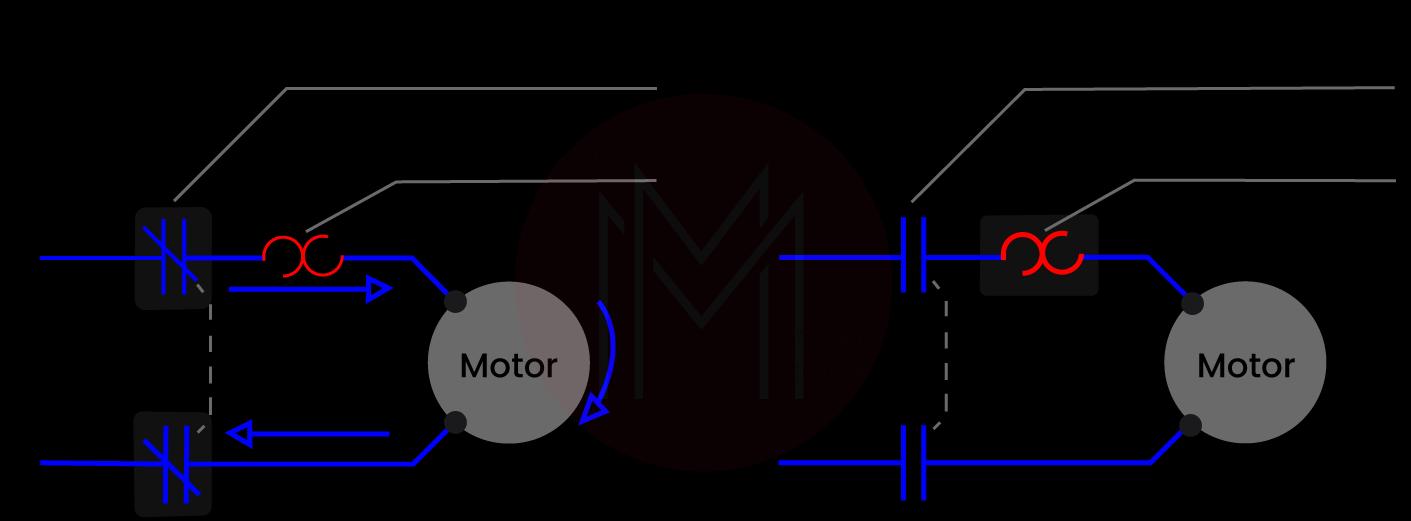

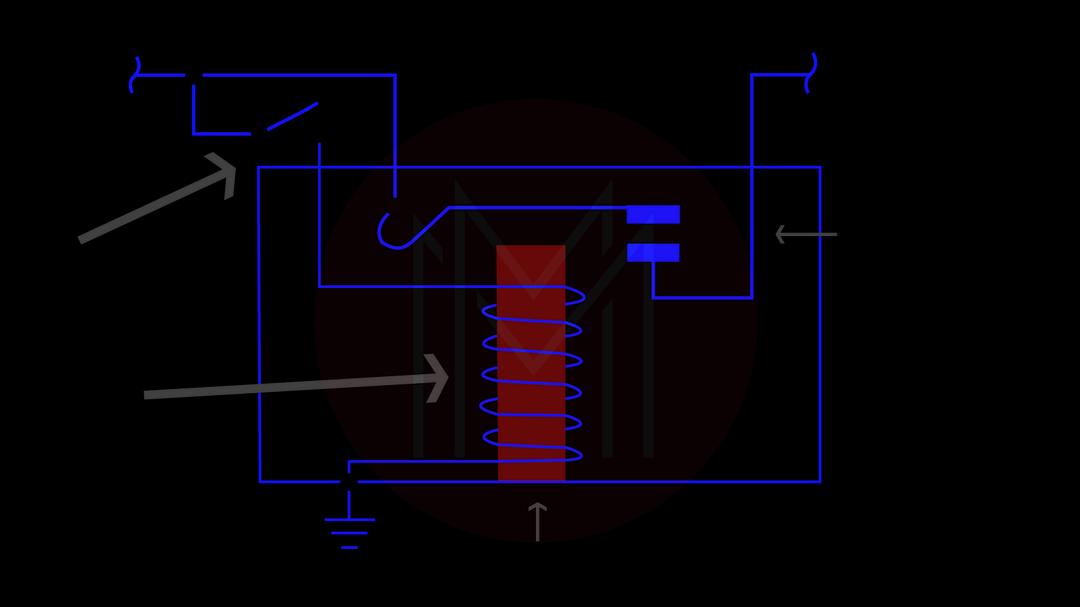

8. What is a relay?

Ans: Relays are used to isolate one voltage degree from another. A PLC can be used to manipulate the operation of a medium-voltage motor, possibly 2,300V or 4,160V. A relay is used to energize the starter, which, in turn, switches the motor voltage at the same time as the PLC controls the relay.

Wired to offer a manage sequence, relays will also be used for easy management schemes in which a PLC might show uneconomical.

9. What are DC Relays?

Ans: DC relays encompass a cord wound on a bobbin that is positioned over a ferromagnetic core. When contemporary is carried out to the coil, flux is triggered withinside the ferromagnetic core, inflicting the contacts to close.

10. What are AC Relays?

Ans: AC relays are synthetic, much like their DC counterparts. If AC contemporary is carried out to a DC relay, the relay will pulse on the frequency of the AC contemporary.

11. Different types of Relays?

Ans:

- Electromagnetic Relays

- Latching Relays

- Electronic Relays

- Non-Latching Relays

- Reed Relays

- Polarized Relays

- Overload Protection Relays

- Solid State Relays

- IDMT Relays

- Thermal Relays

- Differential Relays

- Distance Relays

- Automotive Relays

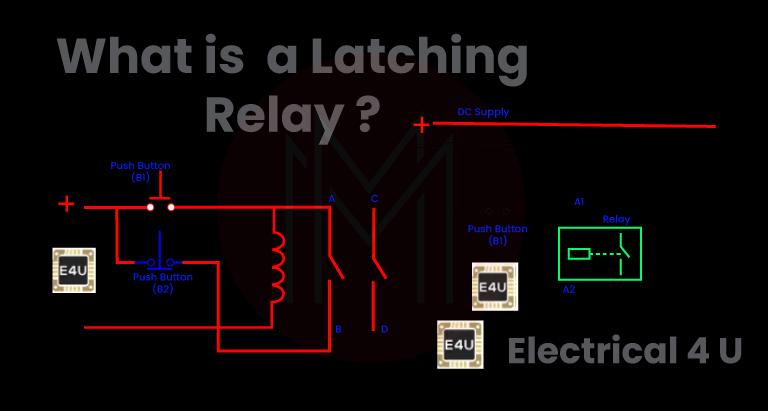

12. What are Latching Relays?

Ans: A Latching Relay is a relay that keeps its nation after being actuated. That is why those styles of relays also are referred to as Impulse Relays Keep Relays or Stay Relays. There is an inner magnet in a latching relay.

When the contemporary is provided to the coil, it (inner magnet) holds the touch function, and therefore it calls for no energy to keep its function. So, even after being actuated, the elimination of the pressure contemporary to the coil can't flow the touch function however stays in its remaining function.

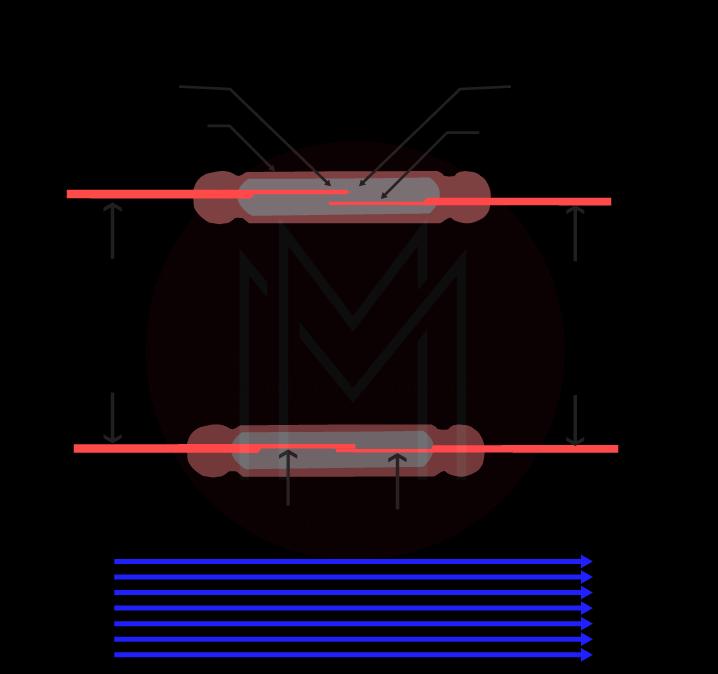

13. What are reed Relays?

Ans: These relays are designed with the aid of using coils wounded round a reed transfer. The reed transfer of the relay acts as an armature, and it's far a tumbler tube or pill full of an inert fuel line inside which overlapping reeds (or ferromagnetic blades) are hermetically sealed.

The overlapping ends of a reed encompass contacts in order that enter, and output terminals may be related to them. When the energy is provided to the coils, a magnetic subject is produced. These fields motivate reeds to be drawn together; thereby, their contacts make a closed route thru the relay.

Also, at some stage in the de-energizing technique of the coil, reeds are separated aside with the aid of using the pulling pressure of the spring connected to them.

14. What are polarized relays?

Ans: It is a sort of DC electromagnetic relay furnished with a further supply of an everlasting magnetic subject to transport the armature of the relay. In those relays, the magnetic circuit is constructed with everlasting magnets, electromagnets, and an armature.

Whenever the pressure exerted via way of means of the electromagnet exceeds the pressure exerted via way of means of an everlasting magnet, the armature modifications its position. Similarly, while the contemporary is interrupted, the electromagnetic pressure is decreased too much less than that of the everlasting magnet, and as a result, the armature returns to its authentic position.

15. What do you know about overload safety relays?

Ans: Overload safety relays are specifically designed to offer the over-contemporary safety of electrical automobiles and circuits. These overload relays may be of various sorts together with constant bimetallic strip type, digital or interchangeable heater bimetallic.

The temperature of the motor winding may be predicted by the use of the motor armature thermal model digital overload safety relay via way of means of measuring motor contemporary. Thus, the motor may be correctly included in the use of an overload safety relay.

| Related Article: Hardware Design Development Interview Questions Advanced |

16. What are solid-kingdom relays?

Ans: Solid-kingdom relays use solid-kingdom additives together with BJTs, Thyristors, IGBTs, MOSFETs, and TRIACs to carry out the switching operation. The energy benefit of those relays is a good deal better than the electromechanical relays due to the fact the manipulate power required (to energy the manipulate circuit) is a good deal decreased in comparison with the energy to be controlled (switching output) via way of means of those relays.

These relays may be designed to paintings for each AC and DC supply. SSRs are categorized into specific sorts, but essential kinds of those relays consist of photo-coupled SSRs and transformer-coupled SSRs. In transformer-coupled SSR, a small DC contemporary is provided to the number one of the transformer via a DC to AC converter.

This contemporary is then transformed to AC and stepped as much as function the solid-kingdom device (TRIAC on this case) in addition to triggering circuit. The diploma of isolation among the enter and output relies upon the layout of the transformer.

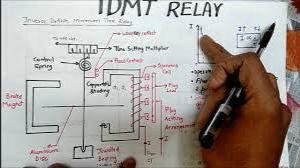

17. IDMT Relays?

Ans: This sort of relay offers a definite-time contemporary feature at better values of the fault contemporary and an inverse time-contemporary feature at decreased values of the fault contemporary. These are broadly used for the safety of distribution traces, and they provide to set the boundaries for contemporary and time settings.

In this sort of relay, the working time of the relay is about inversely proportional to the fault contemporary close to the pickup fee and turns into regular barely above the pickup fee of the relay. This may be performed via way of means of the use of the middle of the magnet, which receives saturated for the contemporary barely extra than the pickup contemporary.

18. Differential Relays?

Ans: As the call suggests, Differential Relays are the ones relays that paint at the 'distinction' of the controlling (or actuating) alerts. Differential Relays function while the phasor distinction of or greater comparable electric portions exceeds a predetermined fee.

A contemporary differential relay operates primarily based totally on the end result of contrast among the value and section distinction of the currents coming into in and leaving out of the device to be included.

Under everyday working situations, the currents coming into and leaving are the same in value and section, so the relay is inoperative. But if a fault approaches inside the device, these currents are no longer the same in value and in section.

This sort of relay is hooked up in such that the distinction between the contemporary coming into and contemporary leaving flows via the working coil of the relay. Hence the relay coil is energized below fault situations because of the specific portions of the contemporary. Thus, the relay operates and opens the circuit breaker with the intention to experience the circuit.

19. What's the position of I/O modules in PLC?

Ans: I/O modules are used to offer I/O signs withinside the shape of easy on and stale commands in PLC, such that an enter module detects the reputation of entering alerts together with push-buttons, switches, temperature sensors, and so on while an output module controls gadgets together with relays, motor starters, lights, and so on.

20. Which programmable languages are utilized in PLC?

Ans: All forms of software programs have their personal programming language. These languages are specific and command the pc to supply outputs. These languages might also additionally or might not be identical for all computers.

The programming languages utilized in PLCs are:

- Instruction List Programming

- Structured Text Programming

- Functional Block Programming

- Ladder Logic Programming

- Sequential Functional Chart

PLC Interview Questions and Answers for Advanced Level

21. How does a Latch coil work?

Ans: Its guidance motivates output to live energized despite the reality that adjustments are stimulated via the popularity connection brought on the I/O. Due to the wrong route having a flow which is a not unusual area, enjoy, then this guidance switch ON output and keeping ON, despite the reality that continuity of not unusual area enjoys otherwise or instrument will be stopped.

22. What do you know about the time counter?

Ans: It sparks off or deactivates the instrument software language length run out a form has shown defined value. Generally, time commands are taken into consideration inner results. It is like relay-kind commands, which are crucial commands for logic.

23. What is the On do away with/ OFF do away with a stopwatch?

Ans: An ON-do away with energizing timer (TON) output guidance each offers time-now no longer on time-movement or measures the length for which some event occurs. Once the rung continues, the timer begins counting time-based absolutely genuinely truly periods (ticks) and counts down until the amassed time equals the preset time.

An OFF-do away with energizing timer (TOF) output guidance offers time-now no longer on-time movement. If the control line rung does now no longer have continuity, the timer begins counting time-based absolutely genuinely truly periods until the amassed time price equals the predefined values.

24. What is a retentive On-do away with-run time?

Ans: Once amassed price run time wants declear despite the reality that not unusual areas enjoy seamlessly or electricity has gone if the retentive ON do away with the result given. If any wrong route flow not unusual area enjoy, time count, depend upon time-based absolutely genuinely truly periods still same values will come.

25. What is a draw close to the control relay?

Ans: A draw close to control relay (MCR) results in guidance that activates or deactivates the execution of a fixed. In the situation of TRUE result, it boosts the predefined result, withinside the region worked via declared clauses getting into rung. If the result is none, then all its outputs are de-energized

26. What are the features of ladder logic?

Ans:

- Left to right electricity flows.

- Factor can't be associated right now with the left factor.

- Contact can't be written after output.

- Each rung includes one output at least.

- Results can be used in the software program.

- Unique results can come multiple times.

- The inputs values are all identified via location.

27. How could you take a look at one PLC device?

Ans:

- Check that every wire between the instruments and systems which crucial to meet community protocol.

- Finding every one the incoming electricity supply suits declared current is prepared.

- Check that every protecting device is prepared for its appropriate adventure settings.

- Checking that the emergency forestalls button works.

- Checking that every one input/output device is associated with the proper input/output elements and offers the proper signals.

- Loading and finding out the software program software software software program.

28. Write different principal organization PLC?

Ans:

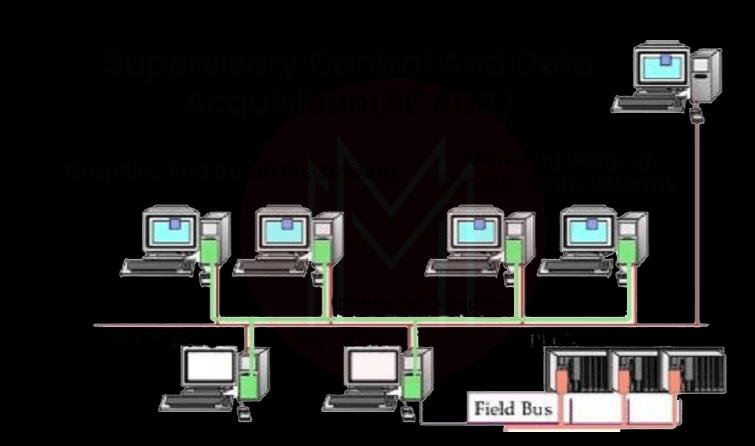

- PLC

- DCS

- Embedded control

- SCADA

29. What are the fantastic, not unusual areas that enjoy gates?

Ans:

- AND gate

- OR gate

- NOT gate

30. What do you apprehend about HMI?

Ans: The full form is a human-machine interface. This process can be referred to as part. The display or on precise tools together with switches. This device has been associated with an industry's program software components in fact so it extrudes user-device information.

31. What changes the range from modular PLCs?

Ans: PLC kits are ready in prefer to perform number one talents which are probably executed withinside the industry. They are bundled and embody a computer and electricity delivery. On the opportunity hand, modular PLCs have several independent systems and parts, they have a couple of I / O structures, and they may be capable of effects being replaced.

32. Tell me the famous company those who expert in this area?

Ans:

- SIEMENS

- Allen-Bradley

- ABB

- Mitsubishi PLC

- Honeywell

- Hitachi

- Motorola

- Schneider Automation

33. Explain RS 232?

Ans: It is a communication medium. Verbal exchange is a manner of speaking together along with your outdoor global via diverse instruments. This is referred to as serial due to the fact the bits of statistics are dispensed serially over an unmarried line. A unique chip referred to manage the serial

34. What are the kinds of RS‐232 gadgets?

Ans:

- DTE: Data Terminal Equipment.

- DCE: Data Communications Equipment.

35. What is grasp/slave config?

Ans: It is mostly an unmarried grasp tool (a PLC) that works with a couple of slave gadgets (sensors). The grasp gadgets ballot the slaves after instruction. Slave gadgets simplest solution while requested queries. They are ideal, the grasp may be stated for activation. The slave gadgets simply gather statistics and skip it to the grasping tool while requesting the same.

36. Explain CRC?

Ans: A cyclic redundancy test (CRC) means an extensively used blunders detection characteristic in virtual networks and garage gadgets to hit upon unintended adjustments to uncooked statistics. Blocks of statistics getting access to those systems are linked with a short seek cost primarily based totally on the rest of a polynomial records section.

37. Can you give me some idea about Hybrid gadgets?

Ans: The hybrid gadget is the mixture of the usage of or greater manipulated systems. Like the mixture of discrete functions. PLCs will be treated so truly and economically, with the state-of-the-art analog non-stop manipulation abilities in DCSs.

38. How do you outline Functional Block programming?

Ans: Data go with the drift is the high precept at the back of an FBD. These kinds of programs, the values by skip-via function block.

39. Explain the Instruction list?

Ans:

- Instruction List (IL) is a textual language of the low stage that has a comparable shape to a primary gadget assembler.

- The IEC has evolved IL via way of means of reviewing the various low-stage languages provided via way of means of PLC manufacturers.

- The IEC has constructed IL via way of means of comparing the various low-stage languages furnished via way of means of PLC manufacturers.

40. Write down the diverse verbal exchange interface supported via way of means of AB?

Ans: DH+, DH485, ETH, Modbus, Device Net, and Control net

Most Common PLC FAQs

1. Is this PLC technician certification program accredited?

Ans: Yes, the PLC Technician Certificate program is accredited in many colleges/universities/ Institutions.

2. what computer software and hardware is required to run PLC programming?

Ans: PC/ Laptop configuration:

- Intel Pentium or equivalent

- 512 MB RAM (1 GB recommended)

- 500 MB of available disk space

- Windows 7 / Windows 8 / Windows 8.1 / Windows 10

- 32 and 64 bit compatible

- Internet Access

- Email Account

3. Can I take a couple of courses at a time? Is there a required course to finish the credential?

Ans: We propose that newcomers take one route at a time. While it's far viable to take guides at a time, newcomers want to be aware of the time dedication and dedicated time that those courses demand.

4. What is PLC programming used for?

Ans: A PLC programming is mainly used to control machinery. An application written for a PLC is composed essentially of commands to show on and stale outputs primarily based totally on enter situations and the inner application. In this respect, it's miles just like how a popular laptop utility is used.

5. What are the four fundamental components of a PLC?

Ans: The 4 fundamental components of a Programmable Logic Controller include the strength supply, input/output (I/O) section, processor section, and programming section.

6. What happens to PLC as soon as it goes to Fatal Error?

Ans:

- Entering the stop mode

- Light RED LED fault

- Turns off the outputs

If another fatal error occurs, the PLC sets the System Fault LED again; otherwise, the PLC begins normal operation. The S7-200 error is listed in codes, and the special memory (SM) bits are used for monitoring errors.

7. What is the communication Protocol hired in Siemens 300?

Ans:

- Multi-Point Interface ( MPI )

- Profibus

8. What are the Blocks Used in Siemens?

Ans: Linguistics S7 supervisor makes use of DB, OB, FC, PB, and FB.

9. What is the way to make a linkage between PLCs And PLC Programming Software?

Ans: The RS UNIX machine code software is hired for linking the PLC and software program either you will be capable of manually installing the speech verbal exchange settings, or by the usage of the Auto-Configure facility, the software program software can hit upon the verbal exchange settings robotically.

10. What are the numerous Communication Interfaces supported by Ab?

Ans: The typically used verbal exchange protocol in AB consists of DH+, DH485, ETH, Modbus, Device Net, and control Net.

Coming over to the Advantages of PLC programming

PLC is easier to troubleshoot. Additionally, controller programs can be developed offline, allowing you to test programs before installing them, avoiding costly mistakes. Finally, it makes it easy to monitor the inputs and outputs of multiple devices.

If you are having programming knowledge, then it will be very easy for you to understand the flow of the ladder logic diagram. This programming language is relatively simple and easy to understand for you.

By now, you must be well aware of the benefits of Programmable Logic Controllers and how dynamic are the career opportunities in PLC automation.

Conclusion

Technology is ushering in a new era globally. Similarly, there are numerous advantages to employing a software-based PLC. It is critical to properly strategize in order to achieve your goal. We are confident that our efforts will help you ace your PLC interview and get the job of your dreams.

On-Job Support Service

On-Job Support Service

Online Work Support for your on-job roles.

Our work-support plans provide precise options as per your project tasks. Whether you are a newbie or an experienced professional seeking assistance in completing project tasks, we are here with the following plans to meet your custom needs:

- Pay Per Hour

- Pay Per Week

- Monthly

| Name | Dates | |

|---|---|---|

| Hardware Design Development Training | Feb 28 to Mar 15 | View Details |

| Hardware Design Development Training | Mar 03 to Mar 18 | View Details |

| Hardware Design Development Training | Mar 07 to Mar 22 | View Details |

| Hardware Design Development Training | Mar 10 to Mar 25 | View Details |

Madhuri is a Senior Content Creator at MindMajix. She has written about a range of different topics on various technologies, which include, Splunk, Tensorflow, Selenium, and CEH. She spends most of her time researching on technology, and startups. Connect with her via LinkedIn and Twitter .