- Lean Interview Questions

- Lean Manufacturing Tools

- Lean vs Six Sigma

- Six Sigma Interview Question and Answers

- What is Lean Management? - A Complete Tutorial

- What is Six Sigma Green Belt?

- Six Sigma Tools

- What is Lean Six Sigma - The Definitive Guide

- Six Sigma Companies

- Six Sigma Methodology

- Six Sigma Projects and Use Cases

- Six Sigma VS Kaizen

Digital transformation has been the most current tagline of this decade. New tools and technologies are supporting this digital transformation journey of big and small companies as they get the best output in a fast-paced competitive environment. But this digital transformation requires an independent technology implementation to resolve the problems in troubleshooting or production process. Even though digital transformation accelerates the company’s growth, it has to be supported by the management methodologies of business transformation and quality control.

Considering all these requirements, an American-based company “Motorola” built the concept of a quality management process in 1986. Over time, it has been developed into a theory of methods and principles intended for business transformation using a defined process. That theory is “Six Sigma.” Six Sigma is a group of management techniques and tools built to enhance the capability of the business process by minimizing the possibility of error. It is the data-driven approach that eliminates and reduces defects and maximizes profits. In this Six Sigma technique blog, you will master all the essential and popular six sigma techniques that are implemented in leading organizations like Amazon, Atos, Bank of America, BAE Systems, etc.

| Six Sigma Techniques - Table of Contents |

What are Six Sigma Techniques?

Six Sigma Techniques are the blend of data and statistical analysis techniques like process design and mapping and proven quantitative and qualitative techniques for getting the required output.

| If you want to enrich your career and become a professional in Six Sigma, then enroll in "Six Sigma Green Belt Training" This course will help you to achieve excellence in this domain. |

Why Six Sigma Techniques?

Six Sigma Techniques combine several robust tools for use in the constant enhancement of programs and projects. There are several useful quantitative and qualitative techniques that are included in the Six Sigma toolbox. While several methods are utilized for a particular purpose, critical and essential techniques are commonly utilized in every six sigma project.

What do Six Sigma Techniques mean?

Six Sigma techniques are used to assess every step of the business process. They offer methodologies to enhance the business structure's efficiency, the process's quality, and the bottom-line profit. Six Sigma techniques emphasize restricting the fluctuation of the business processes and quality management of the process by deploying problem-solving statistical methods.

What are the Steps of Six Sigma?

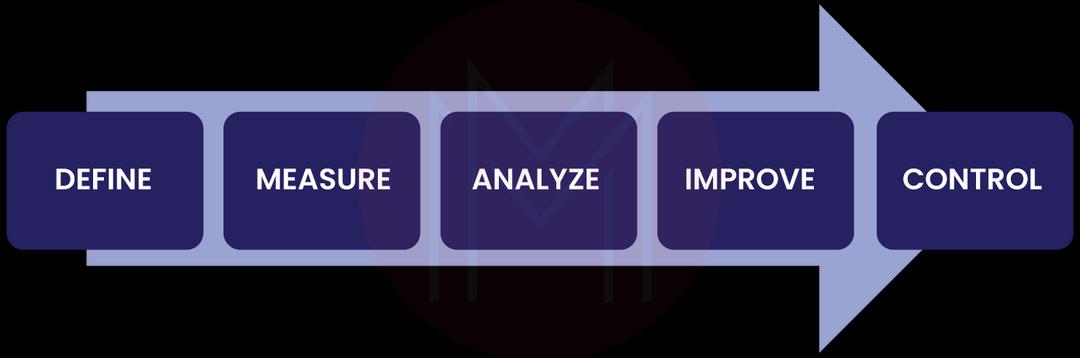

The Six Sigma steps for process enhancement, also called DMAIC, are straightforward and direct.

Step 1: Define the Problem: Build the problem statement, project charter, process map, customer requirement, and goal statement.

Step 2: Measure the Process: Gather the data on the current issues and performance. Check whether the data is secure and upgrade the project charter as required.

Step 3: Analyze the reason for the issues: Review the process and the data that was gathered, show the data, investigate it, confirm the reason for the issues, and continue upgrading the project charter as required.

Step 4: Control: Elaborate the process, continue monitoring, and utilize discoveries elsewhere in the business, if feasible.

Step 5: Enhance the process: Determine the solutions for fixing the issues and create the process maps for new solutions. Run the steps for implementing the latest fixes and measure enhancement.

Six Sigma Process of Business Transformation

DMAIC is the standard approach utilized by Six Sigma professionals. Six Sigma utilizes data-driven management utilized for enhancing and optimizing business processes. The integral framework is a strong customer focus and strong use of statistics and data. The six Sigma process of the DMAIC method has the following phases:

Each of the above phases will have the following steps

1. DEFINE

The six Sigma process starts with the customer-centric methodology:

Step 1: The business problem is specified from the customer's point of view.

Step 2: Goals are fixed. What do you want to get? What are the resources you will utilize to achieve your goals?

Step 3: Map the process. Check with the shareholders that we are on the appropriate track.

2. MEASURE

This phase emphasizes the measures of the project and the tools utilized in the measurement. How can we enhance? How can we quantify this?

Step 1: Measure the problem in the numbers or with the supporting data.

Step 2: Specify the performance yardstick. Set the limits for “Y.”

Step 3: Asses the measurement system to be utilized. Can it help you get your output?

3. ANALYZE

This phase analyzes the process of finding the influencing variables.

Step 1: Evaluate whether your process is effective and efficient. Does the process help you achieve what we require?

Step 2: Measure your objectives in numbers. For example, decrease the defective goods by 20%.

Step 3: Determine the variations through the historical data.

4. IMPROVE

This phase inquires how the modifications in “X” affect “Y.” In this phase, you will identify how we can enhance the process implementation.

Step 1: Find the probable reasons. Test to discover which of “X” variables found in Process III influence “Y.”

Step 2: Find out the relationships between variables.

Step 3: Setup “process tolerance.” specified as the exact values that particular variables can include and yet fall within the tolerable boundaries, for example, the quality of the product. We can get the process tolerances through tools like validation sets and robust optimization.

5. CONTROL

In the last phase, we find that the performance objective discovered by the prior phase is implemented and that the designed enhancements are acceptable.

Step 1: Validate the measure system to be utilized. https://go.microsoft.com/fwlink/?LinkId=2085792&lcid=1033

Step 2: Setup the process capability. Is the goal being achieved? For instance, will the objective of decreasing the defective goods by 20% be achieved.

Step 3: Once the prior setup is met, run the process.

Six Sigma Techniques

Six Sigma utilizes a mixture of data analysis and statistical tools like process design and mapping and demonstrates quantitative and qualitative techniques to get the required outcome.

1. Brainstorming

It is the essential process of the problem-solving method and is frequently used in the “enhance” stage of DMAIC methodology. It is the required process before anyone begins utilizing any tools. Brainstorming includes vigorous ideas and creative approaches to solving a problem using intensive group discussions.

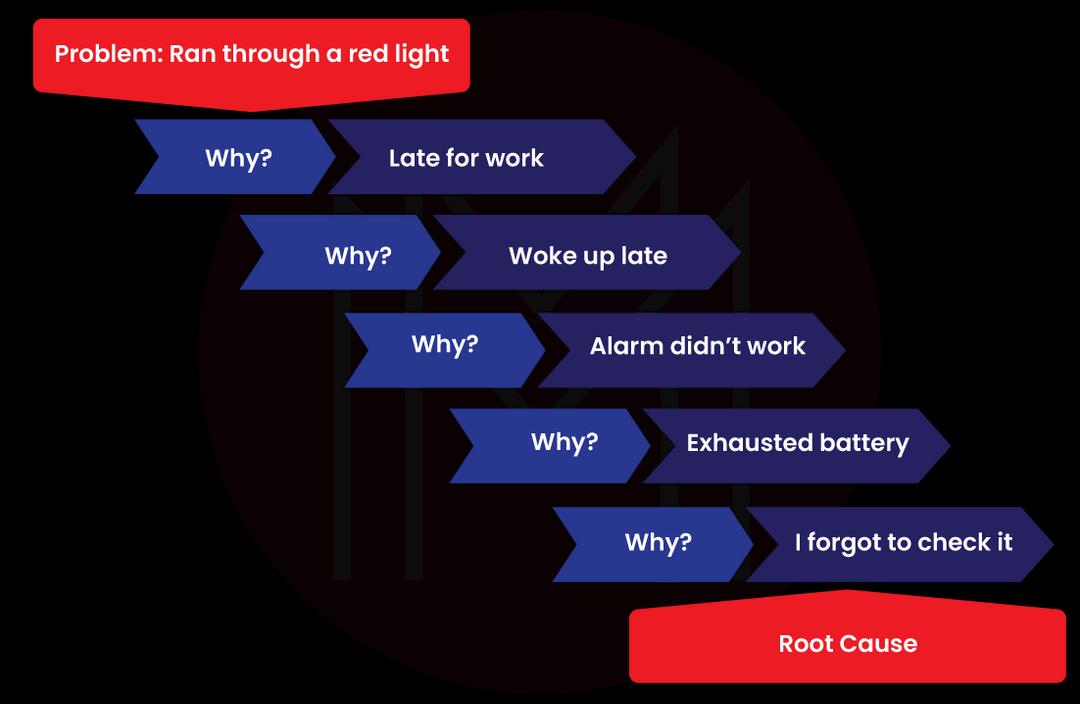

2. The 5 Whys/ The Root Cause Analysis

This technique enables us to find out the root cause of the problems in consideration and is utilized in the “analyze” phase of the DMAIC cycle. In the 5 Whys techniques, the question “Why” will be asked again and again, ultimately leading to the core issues. Even though “five” is a rule of thumb, the exact number of questions can be fewer or greater, whatever it wants to get clarity.

3. Voice of the Customer

This is the mechanism utilized for capturing the “customer voice” or the customer feedback in either external or internal ways. This technique is intended to give the customer the best services and products. It grabs the changing requirements using indirect and direct methods. The voice of customer methodology is utilized in the “define” stage of the DMAIC methodology, generally to specify further the problem to be handled.

4. Benchmarking

Benchmarking is the technique that utilizes a set standard measurement. It includes making comparisons with other enterprises to get an independent appraisal of the provided situation. Benchmarking can consist of comparing essential processes or departments within the business, comparing the same work areas or functions with the industry leaders, or comparing the same services and products with the competitors.

5. The 5S System

This technique has its origin in the Japanese principles of workplace energies. The 5S System is intended to remove waste and eliminate the problems from ineffective tools, resources, or types of equipment in the workplace. The five steps utilized are: seiso(shine), Seiri(Sort), Seikestu(Standardize), Seiton(Set In Order), and Shitsuke(Sustain).

6. Poka-Yoke

This name comes from the Japanese phrase meaning “to avoid errors” and includes preventing the probability of mistakes from happening. In this technique, employees find and eliminate human errors and inefficiencies in the manufacturing process.

7. Kaizen (Continuous Enhancement)

The Kaizen technique is a robust strategy that offers a continuous engine for business enhancement. It is the process of constantly identifying, monitoring, and implementing enhancements. This is specifically useful practice for the manufacturing sector. Ongoing and Collective enhancements ensure a decrease in waste and

instant change whenever a tiny ineffectiveness has happened.

8. Value Stream Mapping

Value Stream Mapping is the technique that schedules the current flow of information and materials for designing the manufacturing project. The aim is to eliminate waste and ineffectiveness in the value stream and generate leaner operations. It finds seven different kinds of waste and three kinds of waste-eliminating operations.

The Six Sigma Tools

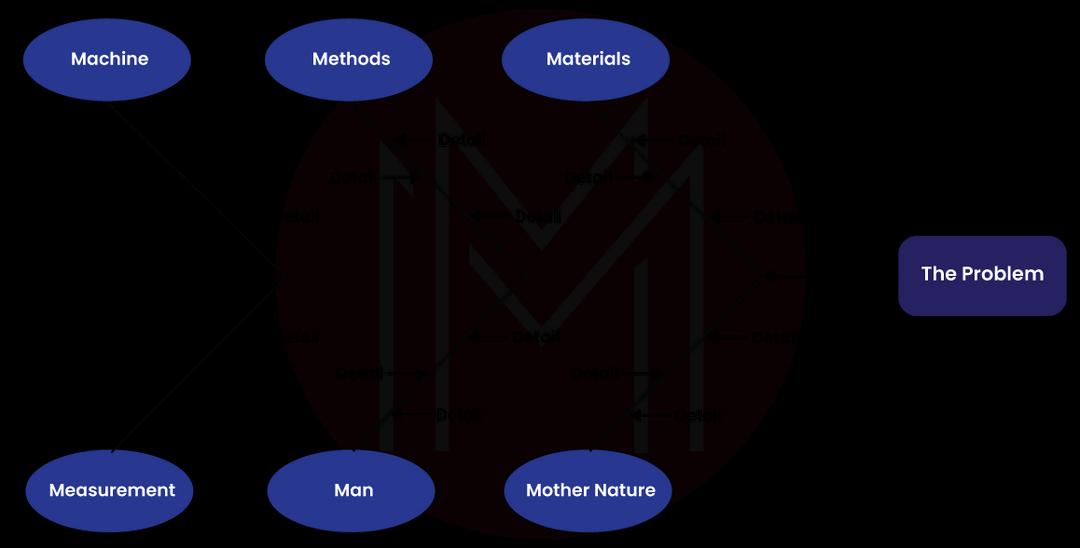

1. Cause and Effect Analysis

The Cause and Effect Analysis diagram is also known as the fishbone diagram because it represents the fish's skeleton. It is one of the most popular six sigma tools since it enables us to research different reasons for a problem. The first phase is carrying out the analysis to find the problem we want to solve. We must write who works on the process and where and when the process happens.

The next step is to write the problem in the box on the left side of the paper. After that, draw the horizontal line till the end of the paper. From there, draw the vertical line dragging over the “spine.” Over these lines, we can write the main reasons behind the problem and think using any probable reasons. We can further break down these reasons into the sub-causes. After completing the diagram with all the probable reasons for the problem, we can analyze our results. The results may require more testing and analysis.

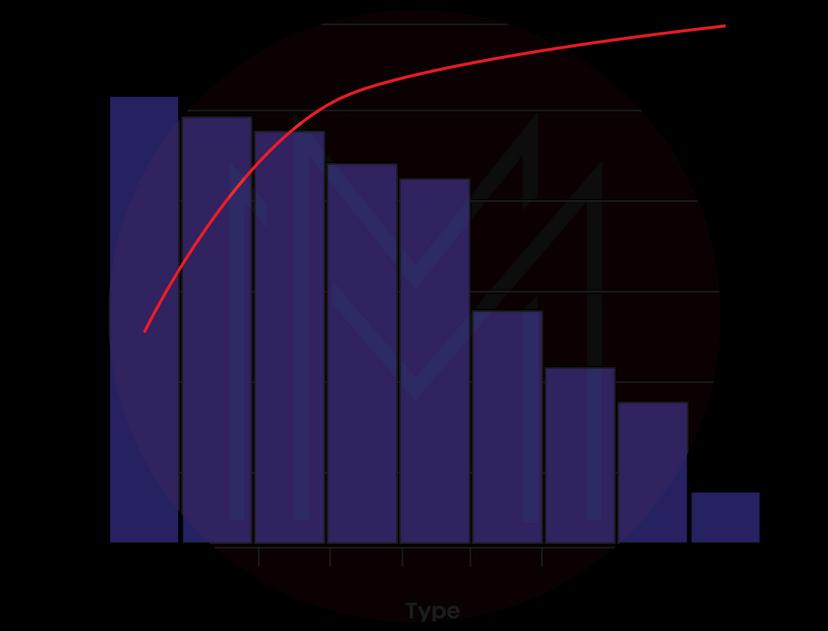

2. Pareto Chart

Pareto Chart is the evident symbol of the Pareto principles: 20% of input gives 80% of output in any given condition. The plan links the perpendicular strip graph and the line graph. The bar graph represents the measures of the different process elements, ordered from highest to lowest one. The line graph demonstrates the merged total of these measures.

The devices indicate what part of the process impacts the most. For building such charts, we first find out the elements of the method and how to govern them. After completing that, we can store this data in the Pareto chart. This will allow you to understand how big the impact on the output of each part has.

3. Control Charts

A time-based visualization is used for improving and monitoring the quality. Control charts are primary tools utilized in statistical process control. There are several control charts to utilize, but the moving and individual range control chart is one of the most straightforward, versatile, and flexible charts to utilize. As it is widely utilized during the process of stability identification, the tool is helpful for constant data flow and for learning non-normality. Thus, the IMR control chart is one of the most frequently used control charts in Six Sigma projects.

4. Histogram

Histogram is utilized to measure the process’s performance by mapping the frequency of different outputs with the histogram. Same as the bar chart, the histogram offers the exact representation of the process variation, allowing us to analyze the process outputs against customer requirements and desired results. Your team can work on the process enhancements if the histogram gives an irregular data division.

5. Flowcharts

Six Sigma utilizes Process Mapping, which can be specified as the flowcharting process to allow the documentation of a particular business process. Documentation involves different aspects of the business processes, like decision points and overall work performance needed for satisfying particular client requirements. These flowcharts are regularly used in making enhancement suggestions.

6. Scatter Charts

Scatter Chart represents a pair of numerical data, with one variable on each axis, to look for the relationship between them. The points will be on a line or curve if the variables are related. The better the relation, the tighter the points will be get closed to the line.

When to use Scatter Charts

- When we have paired the numerical data.

- When our dependent variable will have multiple values for every value of our independent variable.

- While trying to identify whether two variables are associated, like

-

- While trying to find the root cause of the problems.

- After researching the causes and effects through the fishbone diagram for determining objectively whether a specific cause and effect are associated.

- While discovering whether two effects that look to be associated both occur with a similar cause.

- While testing for the autocorrelation before constructing the control chart.

7. Check Sheet

A Check Sheet is a structured and prepared form used for gathering and analyzing the data. This is the generic data analysis and collection tool that can be useful for various purposes, and it is considered as one of the best quality tools.

When to use the CHECK SHEET

- When the data can be collected and observed repeatedly at the same location or by the same person.

- While collecting the data regularly or patterns of problems, events, defect location, defects, similar issues, or defect causes.

- While collecting the data from the production process.

| Related Article: Six Sigma Tools |

Six Sigma Techniques FAQs

1. How important is Six Sigma in Business?

Six Sigma proponents say that its business strategy advantages involve up to 50% of its cost reduction, cycle-time enhancement, little waste of materials, understanding of customer requirements, expanded customer satisfaction, and more reliable services.

2. How does Six Sigma help you in your Career?

Six Sigma is the best way to climb up a career ladder with good job titles and to match salary expectations. Companies like General Electric, IBM, The Hershey Company, Honeywell, Wells Fargo, and Siemens regularly hire candidates to fill the Six Sigma positions.

3. Is it easy to learn Six Sigma?

No, learning six sigma is very easy, but it consumes a lot of time. The Yellow Belt Certification takes up to 4 hours, it takes up to 10 hours to finish the Six Sigma Green Belt certification, and Black Belt takes 16 weeks minimum.

4. How to start a Lean Six Sigma Career?

Lean Six Sigma is the methodology of enhancing performance by statistically reducing variation and removing waste that depends on collective team efforts. To start a Lean Six Sigma career, you must crack the Lean Six Sigma Yellow Belt, Lean Six Sigma Green Belt, and Lean Six Sigma Black Belt.

5. Is Six Sigma a Statistical Measure?

No, Six Sigma is not a statistical measure. It uses data analysis and statistics to analyze and minimize defects or errors.

6. What is the best way to learn Six Sigma?

Follow these steps to learn Six Sigma

- Learn the management policy of your organization.

- Select between Six Sigma and Lean Six Sigma

- Check out which level helps you

- Learn the tests related to it

- Join a training course

- Crack the certification

7. Can I learn Six Sigma on my Own?

Yes, you can learn six sigma on your own and give certification exams from a reputed organization. But joining a course will be beneficial for you by understanding the concepts with industrial examples and case studies.

8. Which Six Sigma should I Start With?

Start with Yellow Belt, as it gives an introduction to Six Sigma for those who are new to the domain. After that, learn Green Belt and Black Belt to get an in-depth understanding.

9. Is Lean Six Sigma Difficult?

No, it is not difficult, but anyone who wants to make a career in it must crack all the certifications with good preparations and disciplined study materials.

| Related Article: Six Sigma Interview Question and Answers |

Conclusion

Six Sigma technologies and tools are used to simplify the business processes for producing the best services and products with minimum defects. Six Sigma techniques include every step of the business process to ensure that the entire process is executed without errors. I hope this Six Sigma techniques blog is sufficient for you to get a deep knowledge of Six Sigma. Getting certified in the Six Sigma Certification Course is a great way to know about the concepts and helps improve your business's work.

On-Job Support Service

On-Job Support Service

Online Work Support for your on-job roles.

Our work-support plans provide precise options as per your project tasks. Whether you are a newbie or an experienced professional seeking assistance in completing project tasks, we are here with the following plans to meet your custom needs:

- Pay Per Hour

- Pay Per Week

- Monthly

| Name | Dates | |

|---|---|---|

| Lean Six Sigma Green Belt Training | Feb 21 to Mar 08 | View Details |

| Lean Six Sigma Green Belt Training | Feb 24 to Mar 11 | View Details |

| Lean Six Sigma Green Belt Training | Feb 28 to Mar 15 | View Details |

| Lean Six Sigma Green Belt Training | Mar 03 to Mar 18 | View Details |

Madhuri is a Senior Content Creator at MindMajix. She has written about a range of different topics on various technologies, which include, Splunk, Tensorflow, Selenium, and CEH. She spends most of her time researching on technology, and startups. Connect with her via LinkedIn and Twitter .